I believe in functional innovation and emotive design that not only excites but solves real problems and makes a positive change to both people and our planet.

Final year project

BUDDI: Increasing safety, independence and opportunity for visually impaired scuba divers.

BUDDI: First Look

BUDDI is an assistive device with the primary aim of increasing safety and independence for visually impaired scuba divers. It functions similarly to a standard blind cane but with the additional benefit of the provision of tactile feedback that informs the user of their surrounding environment based on proximity measurements obtained through the application of ultrasound technology.

BUDDI: A Closer Look

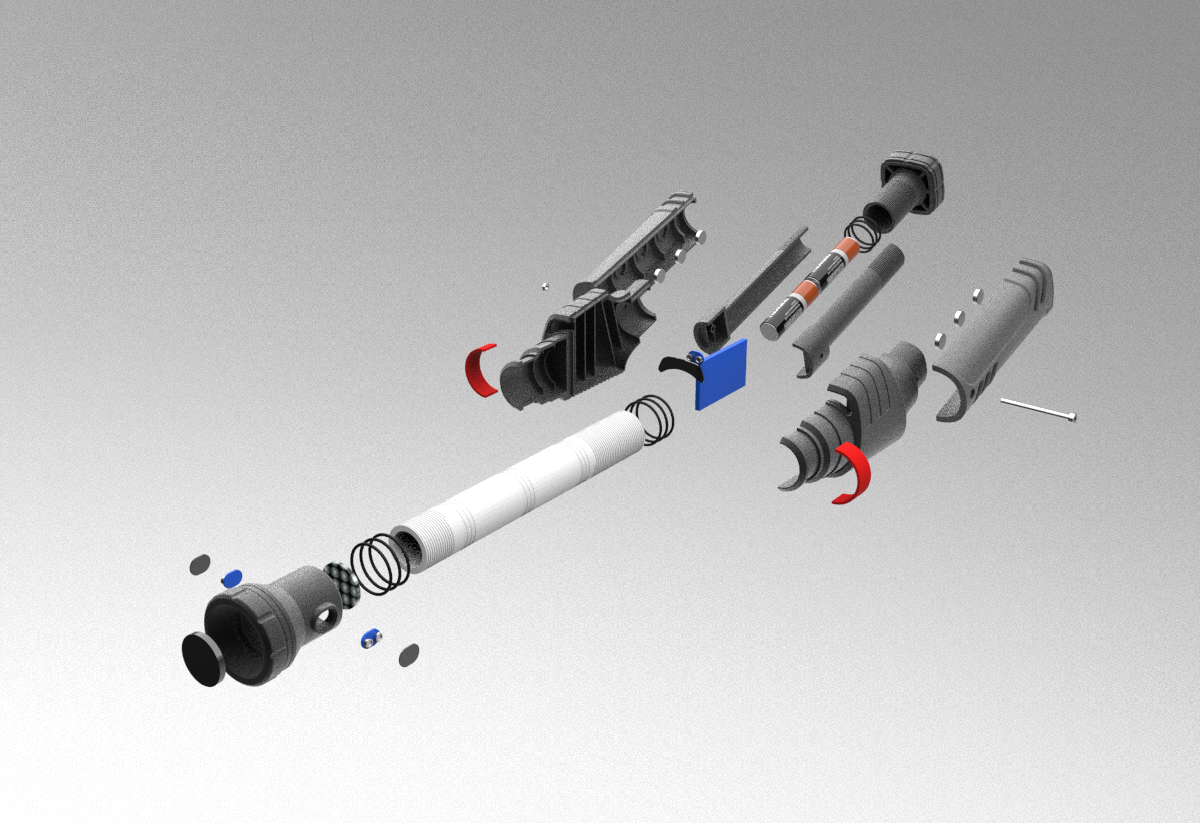

A key requirement of the BUDDI device is its suitability for prolonged underwater use both in shallow water and at depth. This resulted in a number of challenges that needed to be addressed, most crucially the design of a fully waterproof and pressure-proof housing capable of protecting the electronic systems and internals. This required an IP rated seal, supported by o rings and high tolerance screw threads, and careful consideration of design for manufacture including material selection and adaptation of the design for the appropriate production processes and scale. BUDDI incorporates three ultrasonic sensors, the feedback from which informs a tactile motor array that the user can interpret to gain an understanding of their immediate surroundings underwater, both in terms of direction and proximity.

BUDDI: Realising the Concept

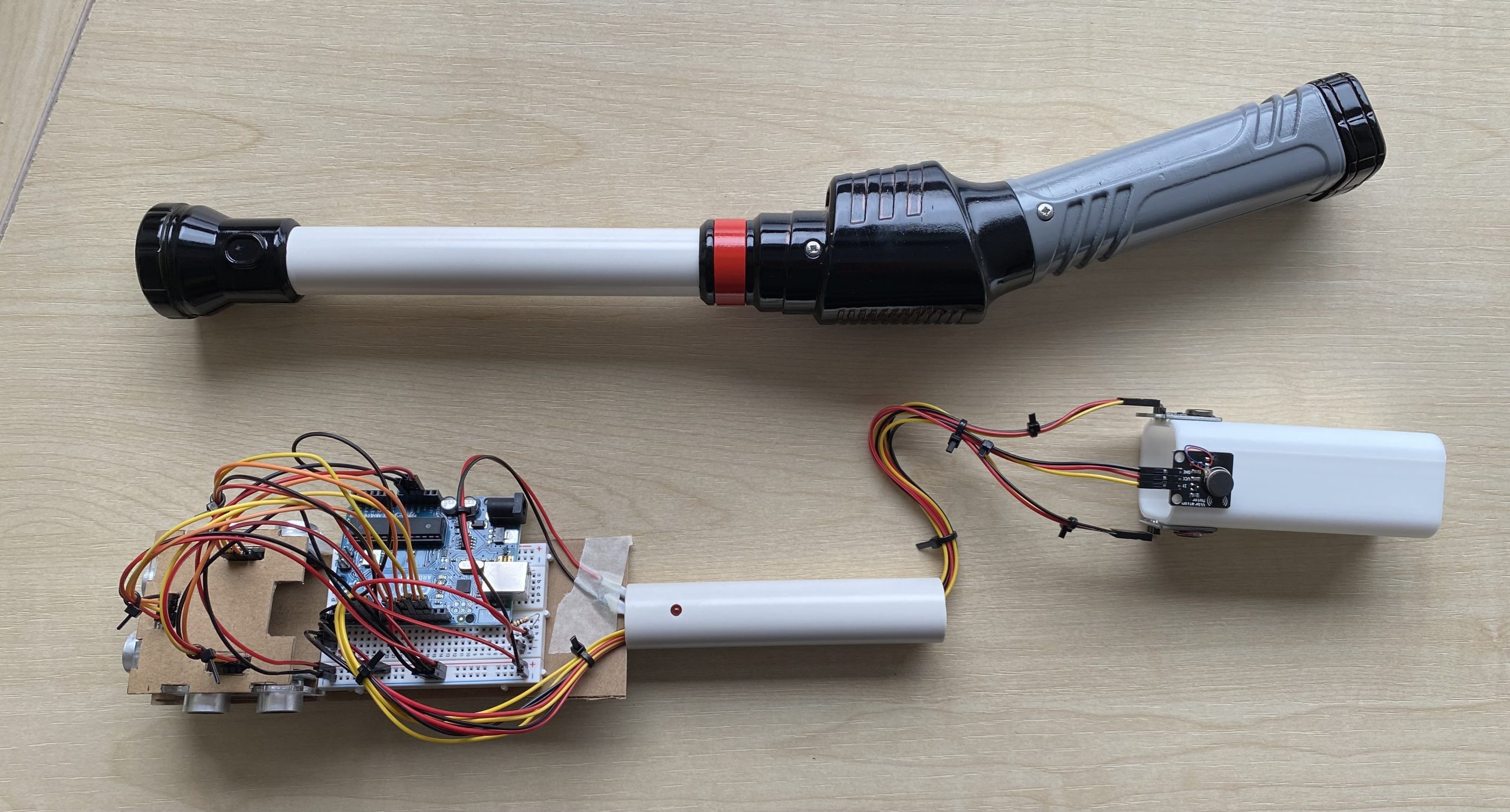

An aesthetic/ergonomic model and functional prototype were used to test the design of the BUDDI device. The aesthetic model consists of a selection of 3D printed parts, painted and finished to a standard that mimics the final design. This model can be assembled and disassembled in the same manner that would be expected of the final device and includes internal features such as ribbing and electronic component mounts.

The functional prototype uses an ARDUINO system to demonstrate the intended functionality with three HC-SR04 ultrasound sensors providing proximity feedback to three corresponding motor modules which vibrate at varying intensity to communicate this information to the user. The battery-powered system is mounted in a cane-style format that allows the operator the ability to freely move the device and better test and explore the capabilities of the prototype.

EZ-GRIP: Combatting Arthritis at Home

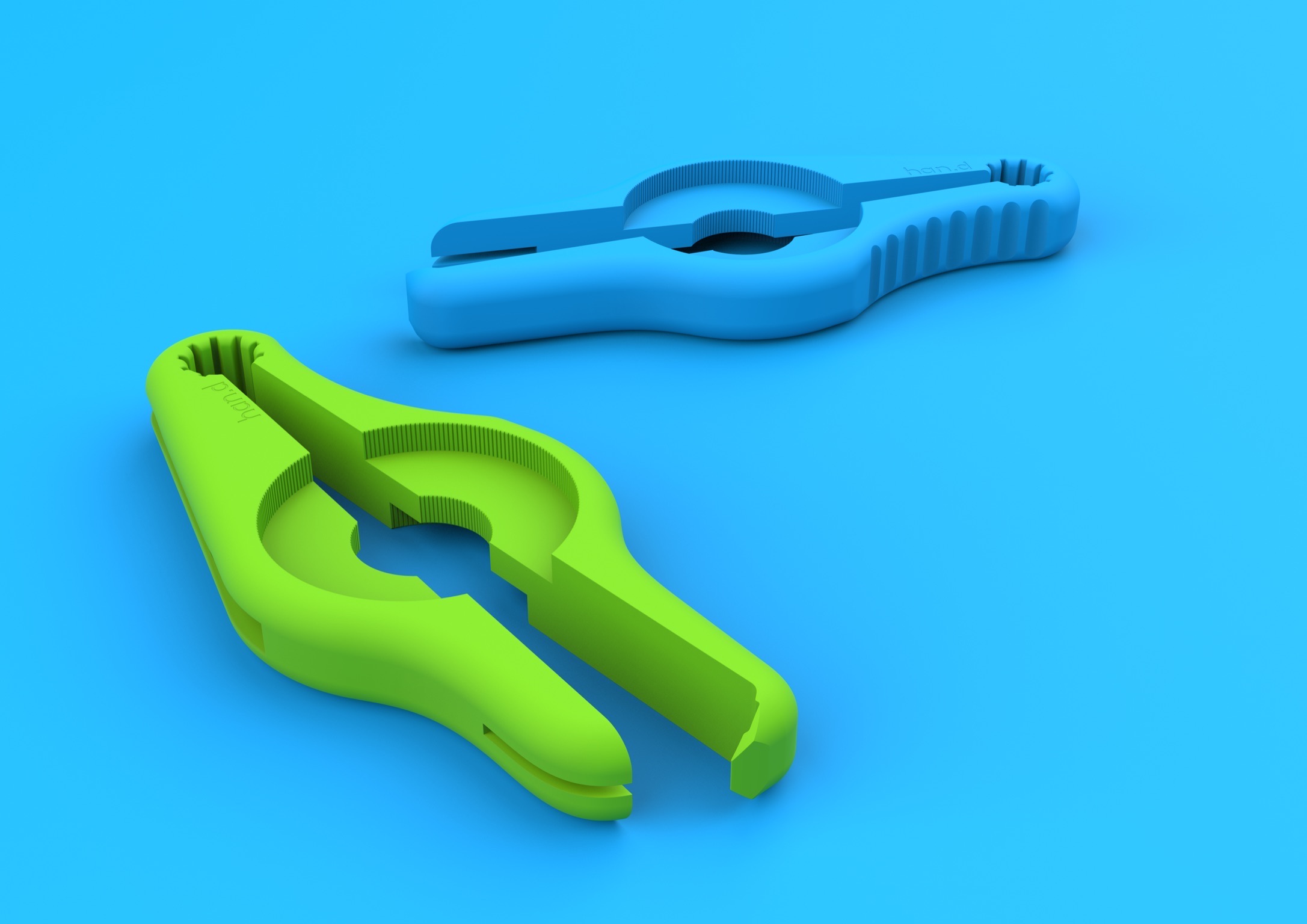

EZ-GRIP aims to assist people living with arthritis and other conditions that result in a reduction in the ability to perform simple tasks requiring fine motor control. It promotes a multifunctional design featuring six tools including three sizes of jar/bottle opener, a pen holder, key turner and ring pull.

EZ-GRIP: Tool in Action

As per the brief, EZ-GRIP is designed to be 3D printed as a single product, and the resulting prototype is used to demonstrate and test some of its functionality through the use of the ring pull, bottle opener and jar opener. The design could however easily be adapted for larger-scale production methods such as injection moulding by reconsidering the internal structure, adapting it to have a consistent wall thickness and incorporating draft angles.

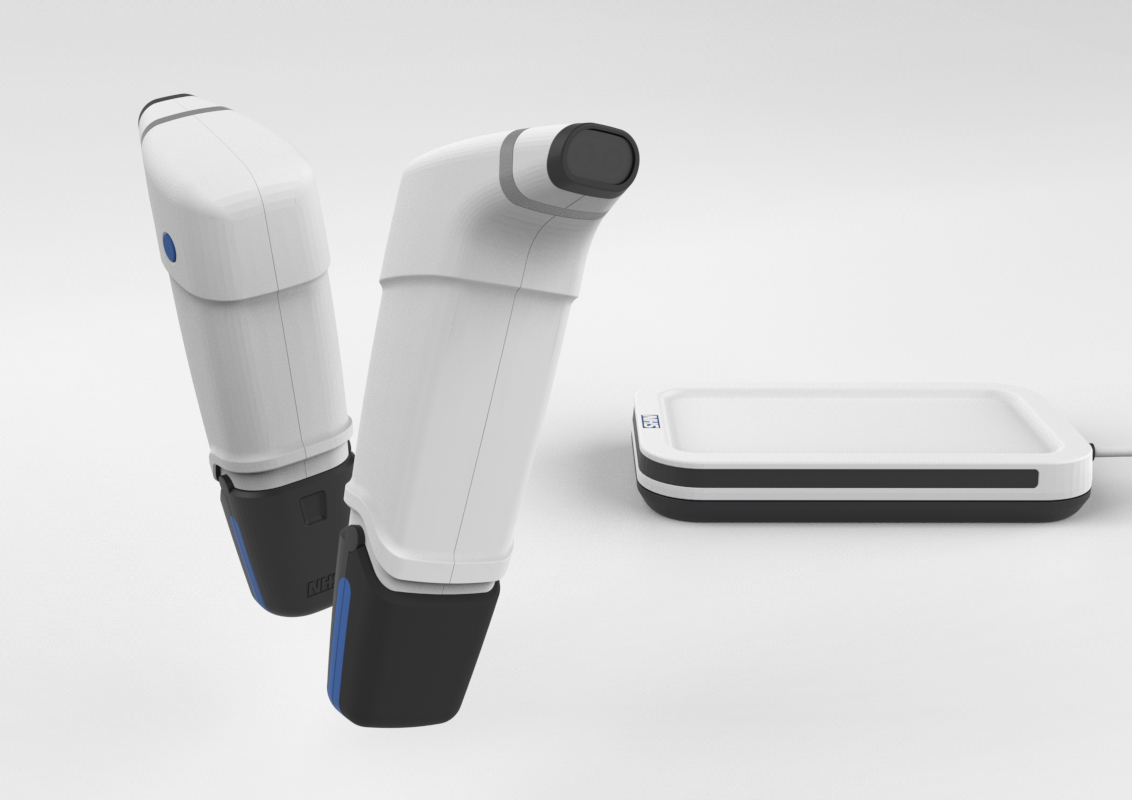

NHS 110: The Step Before 111

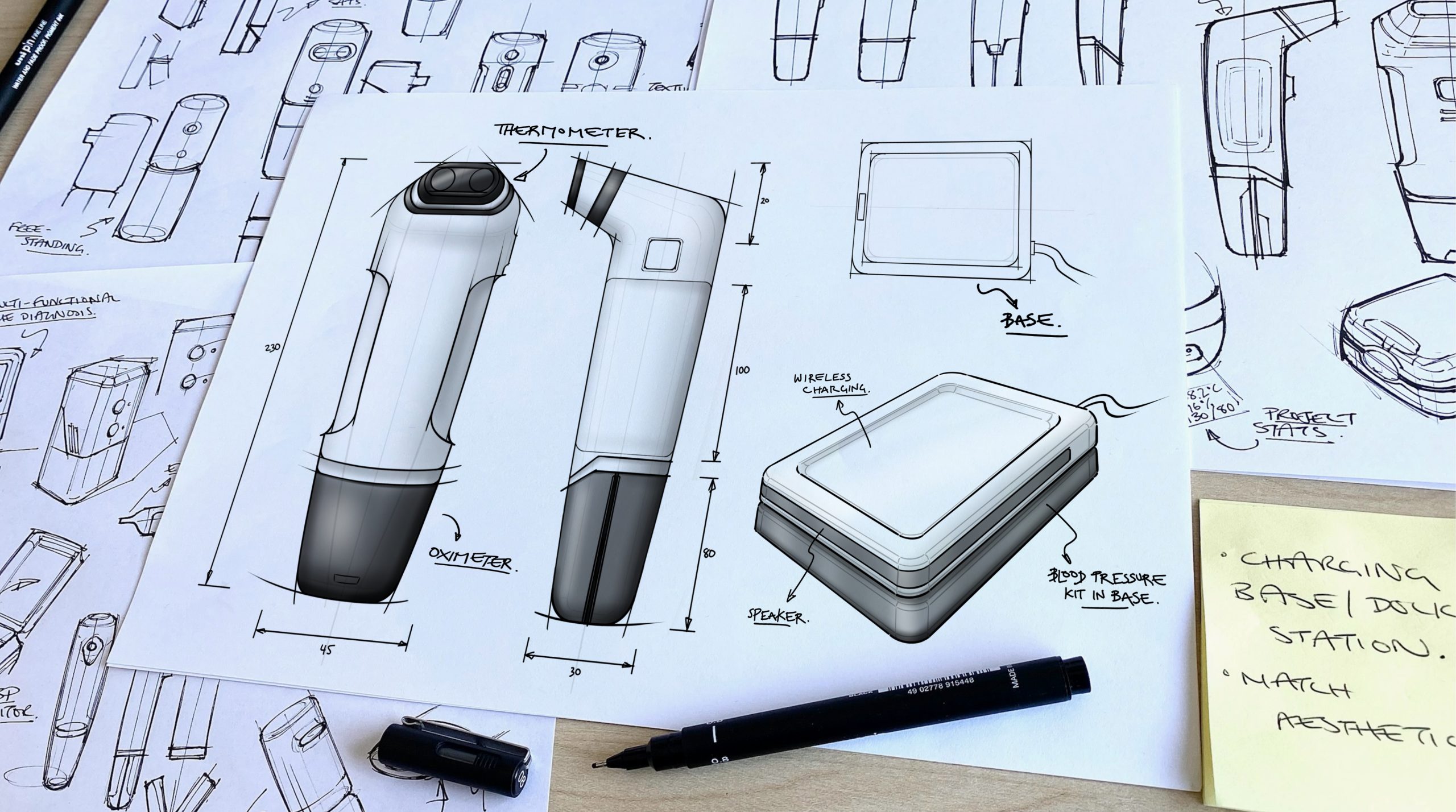

With the NHS facing increasing demand for its services each year, NHS 110 aims to provide an at-home diagnostic service with the goal of reducing A&E attendances and calls made to NHS 111. Combining a thermometer, oximeter and blood pressure monitor, NHS 110 guides the user through the process of using each feature before analysing the results and providing audio feedback and medical advice, directing the user to the relevant services if required. If the system detects serious or potentially life-threatening results, it automatically contacts the local emergency services and provides them with the relevant data.

NHS 110: Designing the Concept

NHS 110 was the response to a live project brief with a timescale of a week in which to produce and present a viable concept. It involved rapid ideation, iteration and confident decision making. Both manual and digital sketching techniques were employed to help communicate the concept both accurately and efficiently.

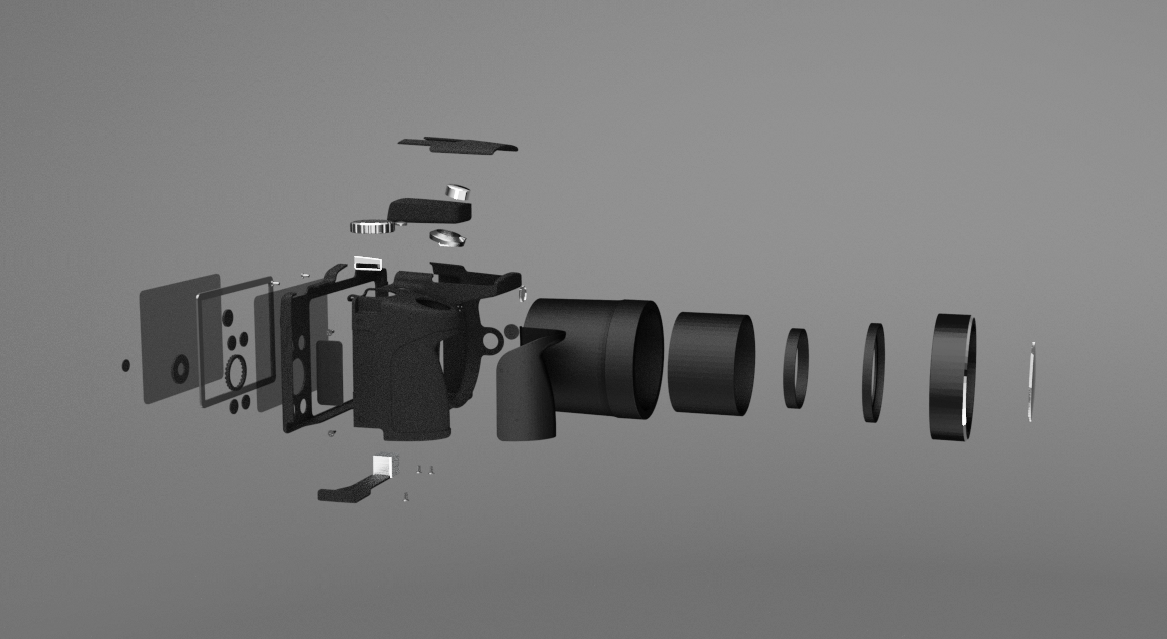

Canon Powershot: Reverse Engineering the Camera

Based primarily on the Solidworks surfacing tools and features, the aim of this project was to reverse engineer an existing product with the target of achieving a combination of G1 and G2 curvature. This was accomplished using tools such as sweeps and lofts to generate the primary surfaces and then using boundary surfaces to manually construct the more organic features, fillets and edge blends. Completing this exercise has significantly developed my CAD skills, modelling efficiency and confidence when tackling more complex features and geometry.

Rebekah Blinman

Final year project

BUDDI: Increasing safety, independence and opportunity for visually impaired scuba divers.

Awards

Alongside my academic work, I was part of an engineering design team responsible for the development of a system used to calculate the draft mark on RNLI service boats which culminated in us receiving the Gold Crest Award for our work. At the start of the Covid-19 pandemic, I took the opportunity to further my learning and develop my skills in Solidworks, working towards and completing both the Solidworks Associate and then Professional qualifications. These were both particularly beneficial when I started my work placement at FSW, equipping me with the skills and confidence to efficiently tackle complex CAD challenges. Following the completion of my placement year and accompanying dissertation, I achieved my Diploma in Professional Studies.

Work Experience

Following the completion of my second year at Loughborough, I spent a year working as an industrial designer at FSW Design in Nottingham. Whilst there, I had the opportunity to work on a number of client-led projects across a range of sectors including consumer, transport and industrial. I was involved in all aspects of the design process from early concept generation right through to prototyping and design for manufacture, the latter being a key emphasis of my work, always designing with the client in mind and considering real-world constraints. Alongside sketch ideation and the generation of CAD data for projects, other aspects of my work involved making technical drawings, creating high-quality product renders in Keyshot and producing the final client presentations. Working during the height of the Covid-19 pandemic came with its own challenges, of course, one of which being remote working which ultimately greatly developed my time management and communication skills as well as allowed me to grow into a more resilient and self-motivated designer.