I have always strived to observe and understand the people or system I am designing for because I believe this will help me design products that are a pleasure to use.

Final year project

Reducing the environmental impact of the footwear industry by implementing modularity

A Modular Approach to Footwear Design

The proposed design is the development of eco-friendly trainers using the concept of modularity. Components can be replaced individually to extend the lifespan of trainers and reduce waste. Designing a method of assembly for footwear components is challenging because the joint area would be under high tension and be continuously deformed during use. The development relied heavily on the use of prototyping and evaluation.

The Components

A shoe design is stripped down to the minimum where 3 key components are identified- upper, heel stiffener and midsole. The latest technological advancements in materials have made this design possible: the upper is a knit made of PA-11 yarn; the heel stiffener is a PA-11 elastomer and the midsole is injection-moulded with PA-11 treated with the process of super-critical foaming- they are all recyclable to further reduce the environmental impact of the footwear industry.

The Assembly

The assembly method features a slot fixing between the heel stiffener and the midsole. It is then reinforced with Salomon laces. The heel stiffener would then wrap around the shoe and be secured to the upper when the shoelace is tied. The use of laces is an idea that was selected after a series of testing. A material that is soft is important for flexibility and a material familiar to users is ideal for the assembly method because they would find the process more intuitive.

The Future

The major innovation of this project is the method of assembly for the shoe modules. As this technology evolves, it can be applied to a number of uses. For example, customisation with components of different colours and even different designs for aesthetic, and styling purposes. With further research on performance-related issues, the technology can be applied to athletic footwear and it may be possible to achieve the idea of 'a pair of uppers and multiple pairs of soles for different sports'.

Smart Sanitiser

In a post-COVID-19 world, another aspect of security should be considered. This is a development of a sanitiser dispenser that connects to other devices such as door locks, smartphones, and computers with the use of IoT technology. An infrared sensor measure body temperature when a wrist is presented and if it is <37 degrees Celcius, the door connected to the sanitiser would be unlocked. To use the IoT technology to the fullest, the temperature data is recorded and stored to find trends or even the cause of the spread of diseases.

The Technology

The infrared proximity sensor also begins the dispensing of alcohol when triggered. The sanitiser is battery-powered. Its unique ring shape and misting nozzles provide a 360-degree alcohol mist spray for hands and even small objects. When taken off the wall mount, it can be used for thorough sanitation of arms and sleeves.

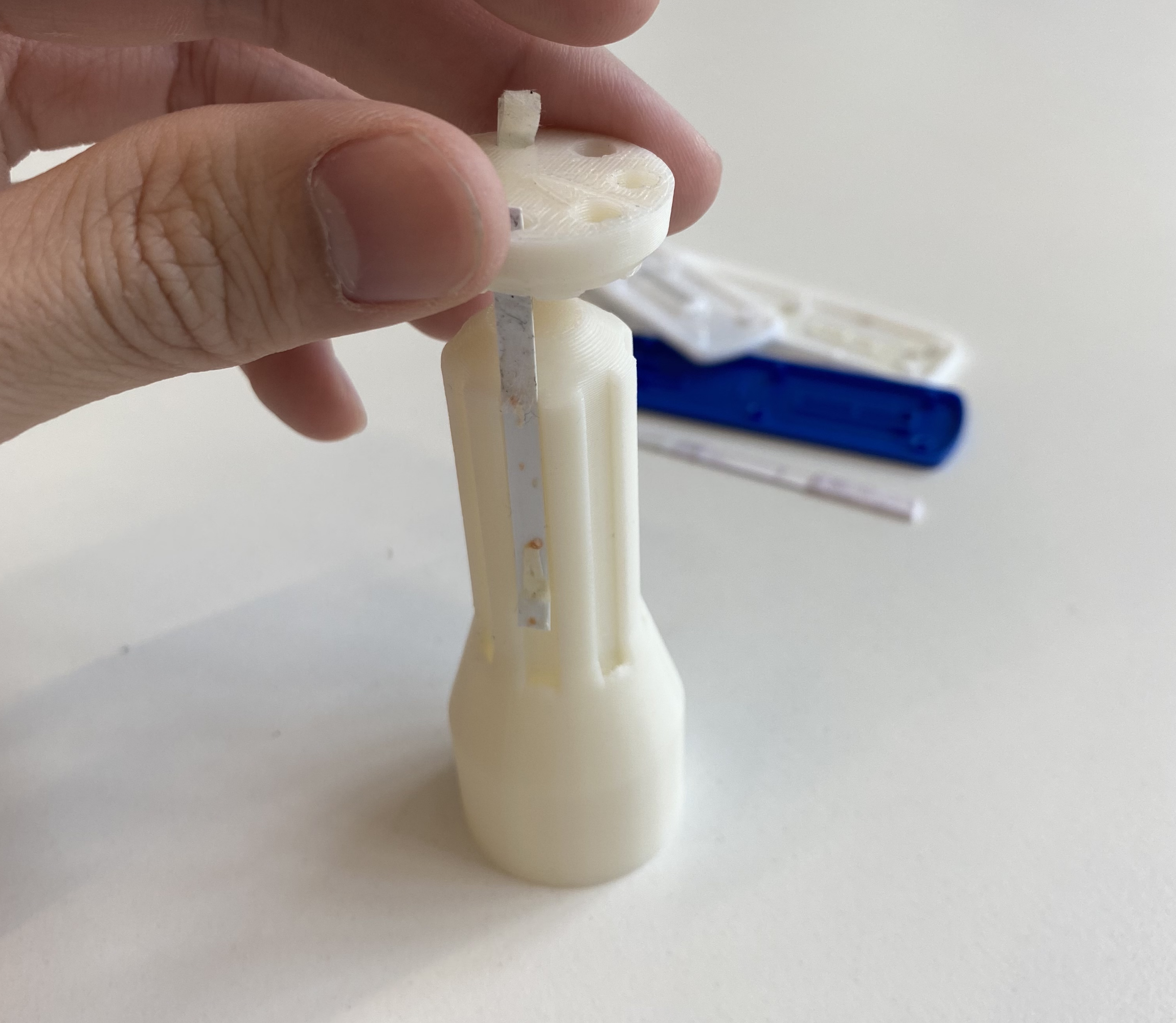

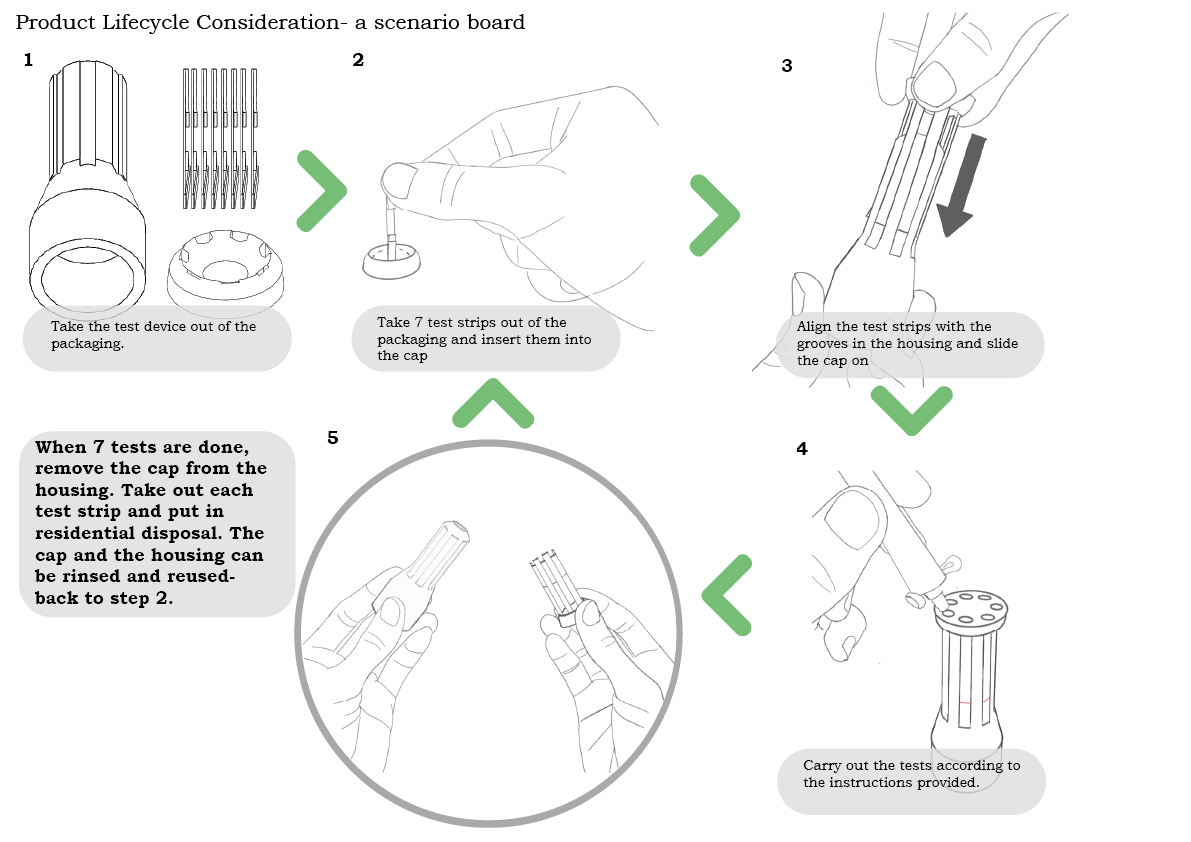

Lateral Flow Test Redesign

This is a reusable Lateral Flow test kit that accommodates 7 test strips. The aim of the project is to improve the end-of-life of lateral flow test kits and a key part of the concept is to reduce demand as well as to meet the demand in a sustainable way. A pack of 7 test kits contains at least 30 grams of unrecyclable plastic. With this redesign, it will now contain a HIPS test-strips housing which weighs 13 grams and can be reused.

The User Journey

Reducing waste is achieved by implementing a method of disassembly so that test strips can be extracted from the polymer cassette after use to enable separate disposal. The user journey is tested with a prototype and further development would optimise the handling of test strips as users who tested found it the most challenging. It is difficult because the slots in the cap and the test strips have a friction fit so that sample added to the aperture would not leak before being absorbed into the sample pads.

Oliver Chang

Final year project

Reducing the environmental impact of the footwear industry by implementing modularity