I am a creative and passionate person who hopes to make a difference by designing innovative and meaningful solutions to modern day challenges.

Final year project

A reusable auto-injector to improve trans people's experience when self-administering HRT.

NOMI - injector and dock

NOMI is a reusable auto-injector which aims to improve trans people’s experience when self-injecting hormones as part of their gender-affirming care. The device allows people to insert a syringe into the injector and their own supply of HRT (Hormone Replacement Therapy) into the dock. Using a vented vial adapter to draw medication from the vial eliminates the need for a drawing needle, reducing waste and hassle, so the user only needs to attach a needle after the medication has been drawn into the syringe. NOMI aims to reduce risk, pain and anxiety compared to traditional methods and allows anyone with access to the medication the ability to use it with little to no prior medical training.

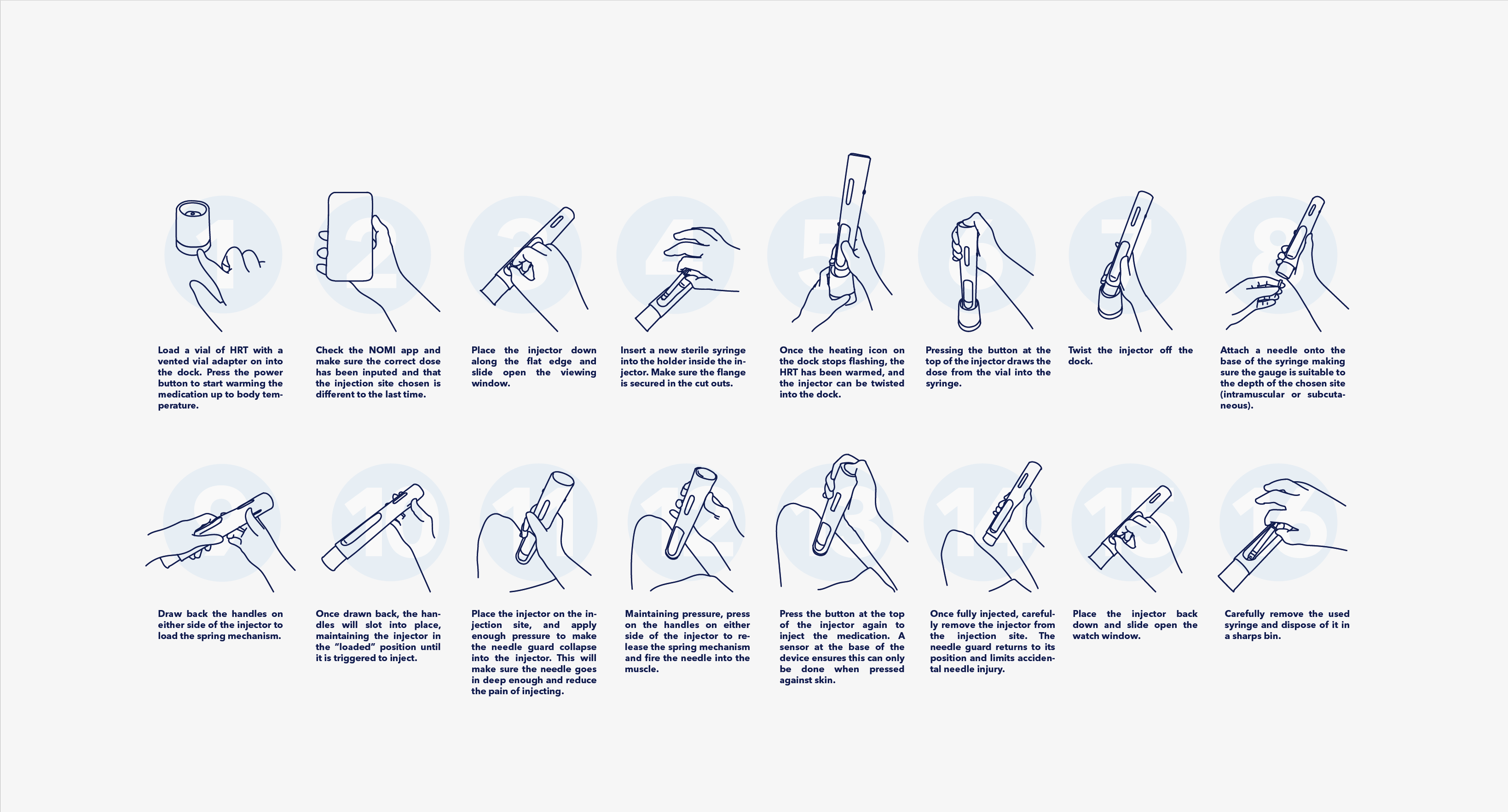

NOMI - storyboard

Making sure that anyone on injectable HRT could benefit from the device was important, as due to NHS waiting lists being so long, it can take upwards of 5 years just to get an initial prescription. Many people are forced to 'DIY' their transition and buy medication online and administer it themselves. NOMI aims to make administering hormones easier for anyone, with functions like heating the vial of medication to thin the oily vehicle and make it less painful to inject. A spring mechanism means the pressure of inserting the needle is taken off the user, and a linear actuator operating the syringe enables accurate dosing and steady delivery into muscle or skin. A collapsible needle guard makes sure the user is applying enough pressure onto the injection site and covers the needle once the injector has been removed.

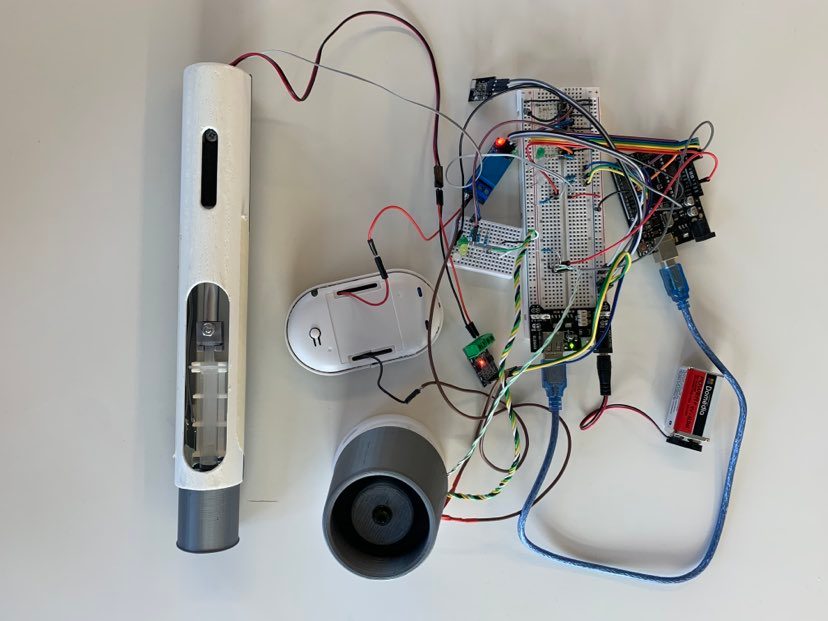

NOMI - prototype

A prototype of the auto-injector and dock was created. Using an Arduino, the device heats the vial in the dock to body temperature, and the injector has a linear actuator controlling the plunger of the syringe in order to draw a desired dose from the dock. A spring mechanism in the 3D printed injector means it can be drawn back and launched into the user's skin or muscle. A linear actuator then plunges the syringe and delivers the dose. A light sensor ensures that the linear actuator doesn't plunge unless the device is pressed against the skin, reducing the risk of accidental or early injection. A screen on the injector walks the person through the key steps, and an app helps with things like reminding them to switch injection sites since their last dose and keeping their dosage up to date based on their last endocrine results.

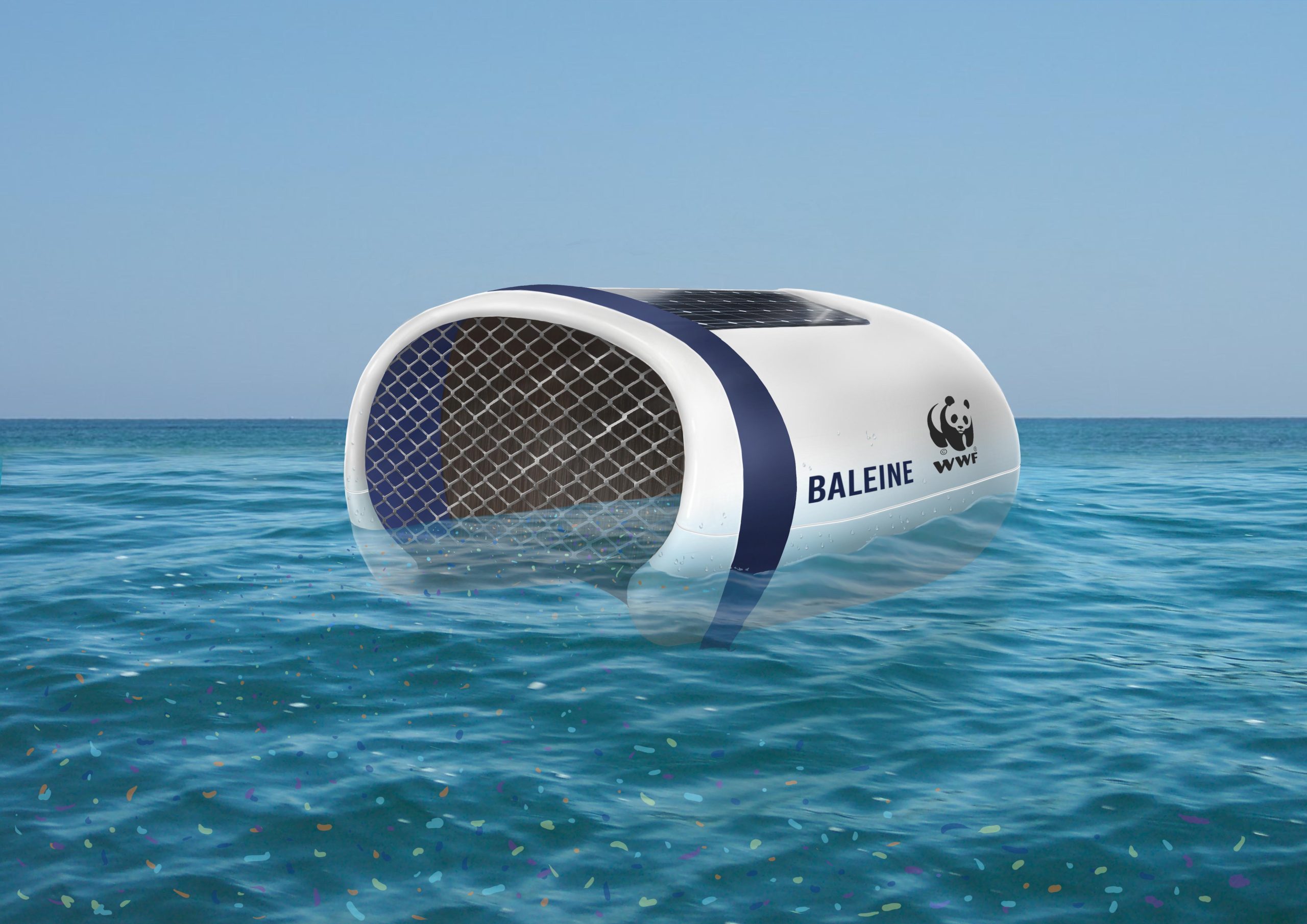

BALEINE – aquatic drone

As part of Live Projects, we were tasked with creating a product for WWF in a week. Baleine is a concept for a network of aquatic drones, that would be used by the WWF to collect surface microplastics in particularly polluted areas of the ocean, where marine life is facing an imminent risk of extinction.

BALEINE - scenario

Baleen whales filter feed by sifting large quantities of water through their baleen in order to retain krill and plankton. However, they also often ingest microplastics floating alongside their prey. Baleine mimics this technique using synthetic baleen made from dense bamboo fibres and collects surface level microplastics as it navigates marine areas. The filter can be removed and the microplastics collected.

Déjà Brew - coffee machine

Déjà Brew is an electro-mechanical group project which involved designing, building, and coding a coffee machine that could rotate and plunge an AeroPress module and produce a cup of coffee. The machine has a voice activation function and can make a specific person’s desired coffee, with different options for stronger or weaker coffee, and an option to add milk.

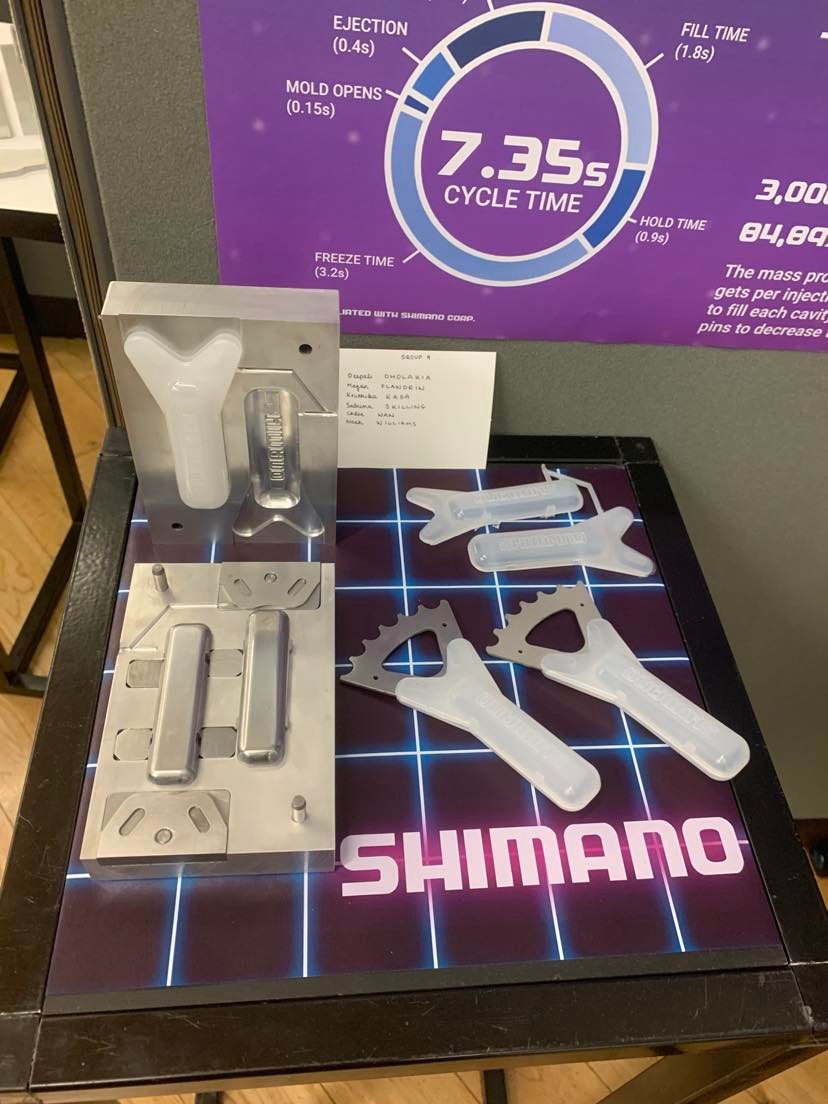

SHIMANO injection moulding project

This was a second-year group injection moulding project. We were tasked with creating a mould for an injection moulded widget that a company could hand out. Our group opted for a Shimano bicycle cog that can be cut and turned into a bottle opener. Many processes were used to create this mould tool including CNC milling, vertical lathes and milling machines.

Various infographic posters and illustrations

Over the years, I’ve made enjoyed making infographic posters for different pieces of coursework and projects, as well as creating cards and illustrations in my spare time.

Megan Flandrin

Final year project

A reusable auto-injector to improve trans people's experience when self-administering HRT.

Work Experience

In my placement year, I did some freelance work, hand painting billboards and signs for shops, bars and businesses in my local area, as well as selling hand-lettered decorative signs, and illustrations online.