A passionate industrial designer with drive to continuously progress and develop. I love the journey I am taken on every time I start with an idea, developing it into a truly worthwhile solution that is both beautifully designed and provides value to the user.

Final year project

EVOS - Tackling global biodiversity loss through reinventing wildlife data collection.

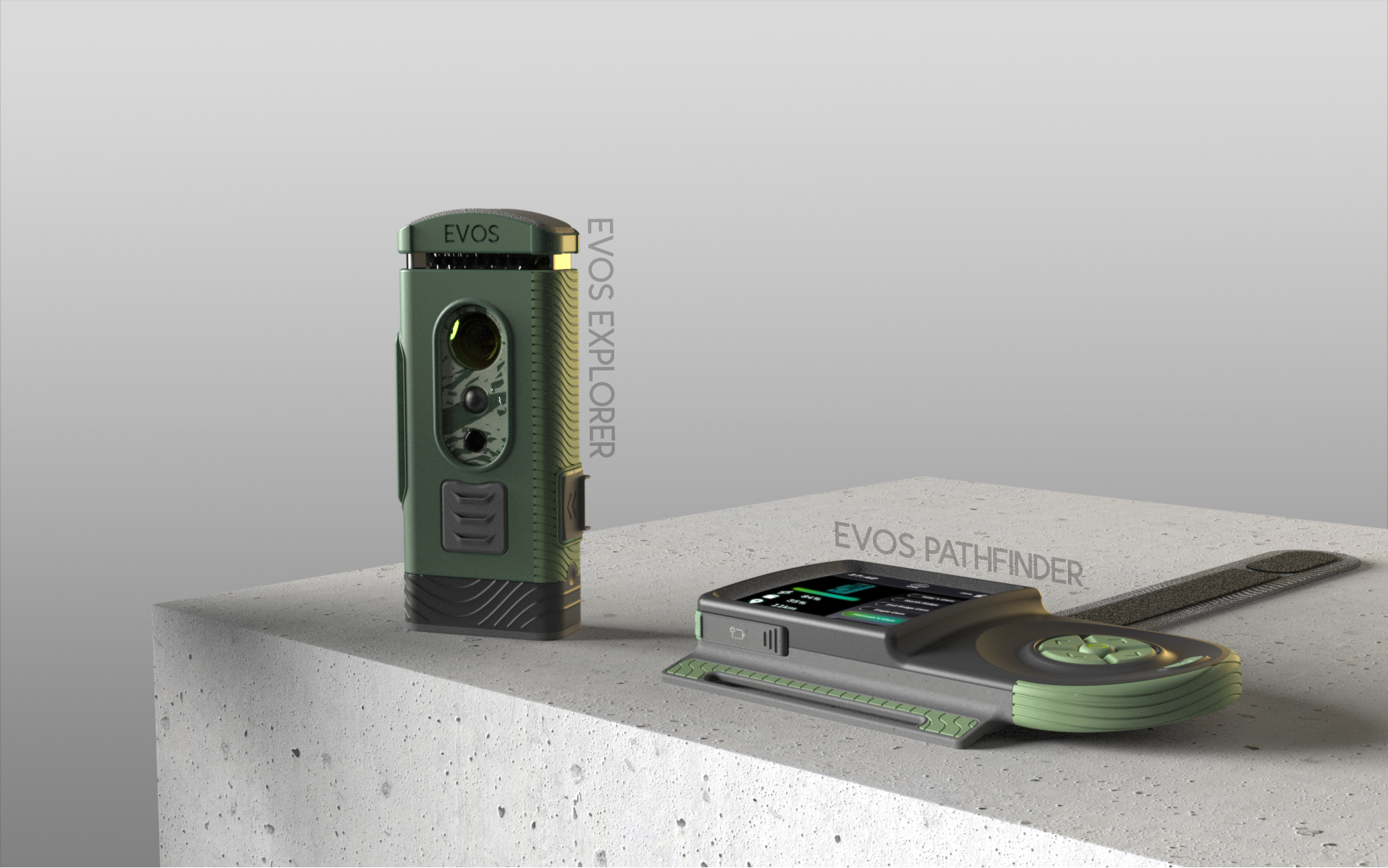

The EVOS Explorer and Pathfinder.

A two-part system, providing much-needed innovation revolutionising wildlife data collection. Firstly, the Explorer has the option to capture images in any direction using omnidirectional technology, widening the possibility for camera locations and increasing the probability of capturing desired targets. Optimised for usage in extreme environments, the Explorer has PTFE vents to keep moisture out whilst equalising air pressure and temperature.

The Pathfinder enables a large number of Explorer units to be set up efficiently, whilst tracking camera locations and status. Data can be retrieved from afar (300m) without disrupting the camera location. The embedded background reduction system within the Pathfinder allows for on the go photo processing, helping to remove false-positive images.

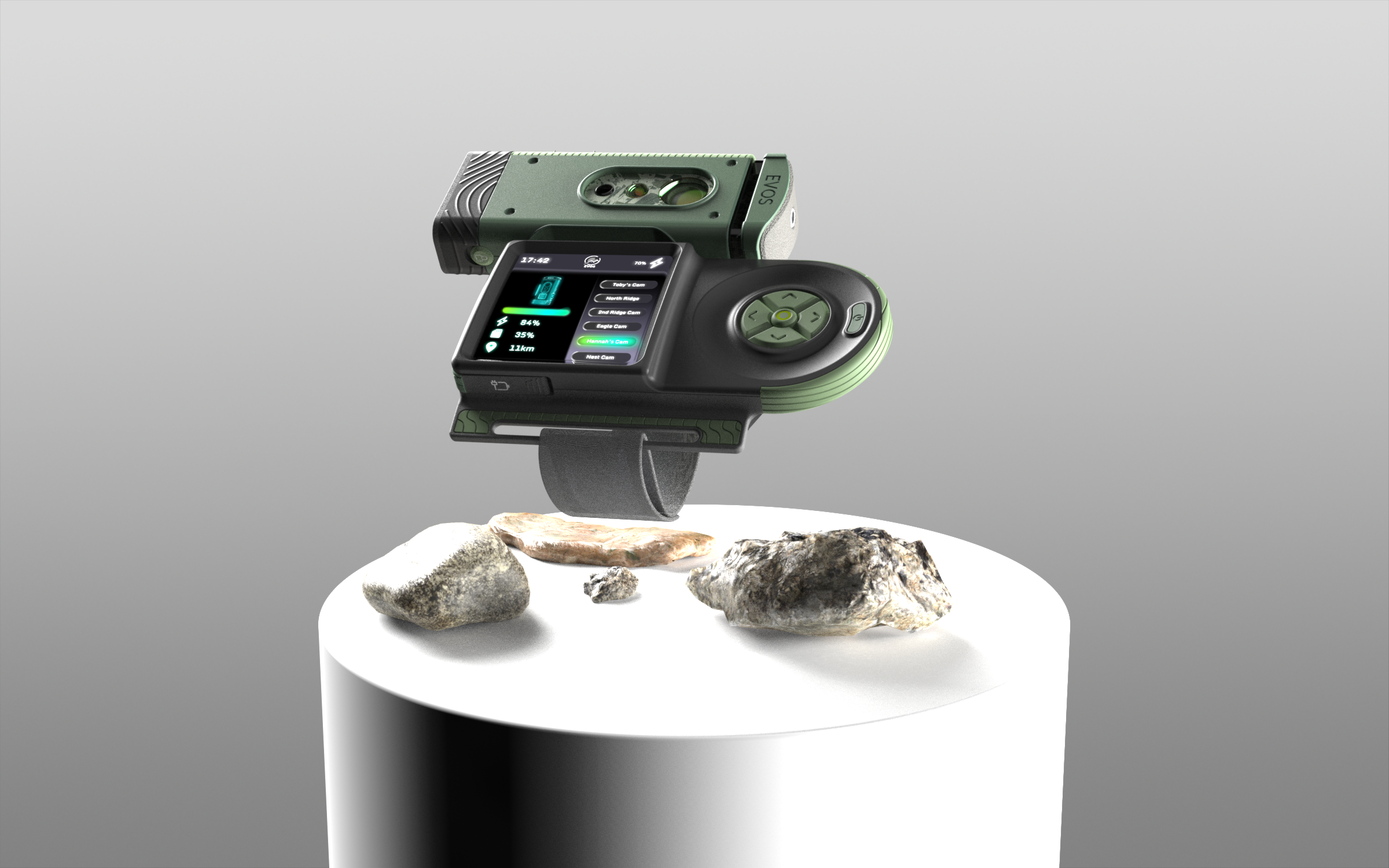

EVOS - System .

The Pathfinder is either secured to the user's arm or clipped to their waist whilst in the field. Explorer units slide onto the Pathfinder to initially set up. Users can quickly register explorer units, and edit or download pre-made camera settings. The Pathfinder would then be used to manage all units within the research project.

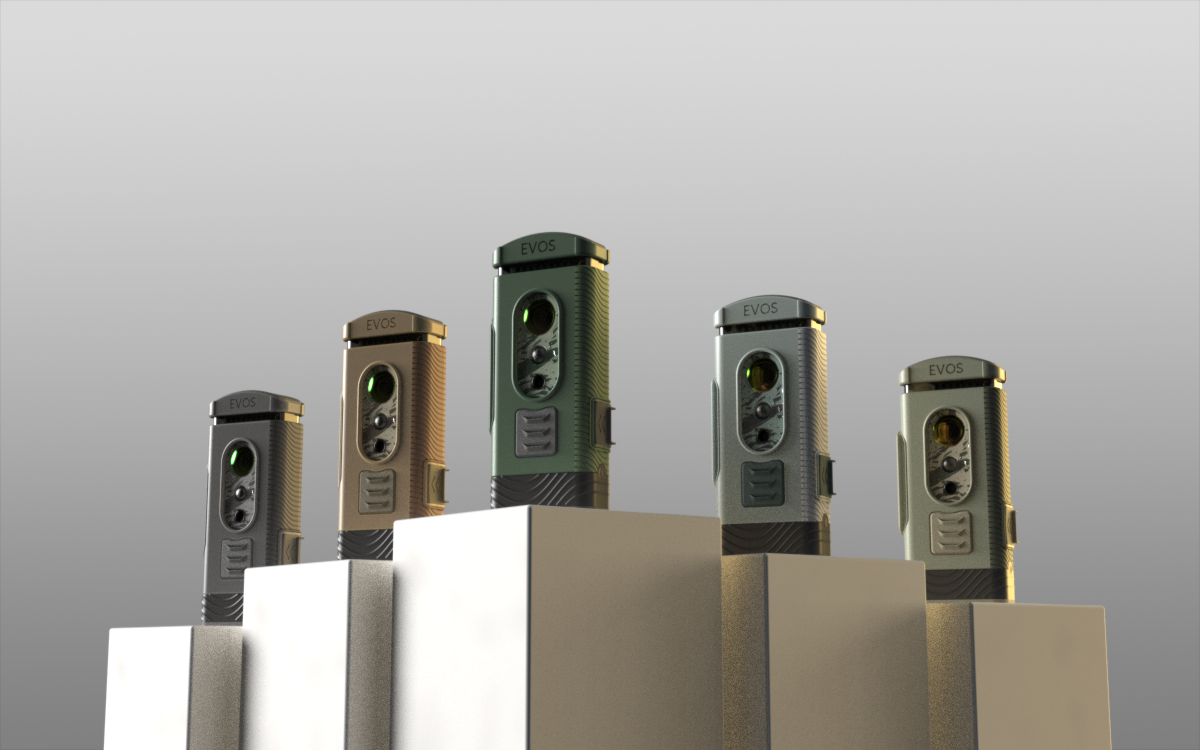

EVOS - Colourways.

The EVOS Explorer will be used all over the world, designed to cope with every environment from the desert to the arctic. Multiple different colourways were created to cater for these different environments, ensuring the product was camouflaged during use.

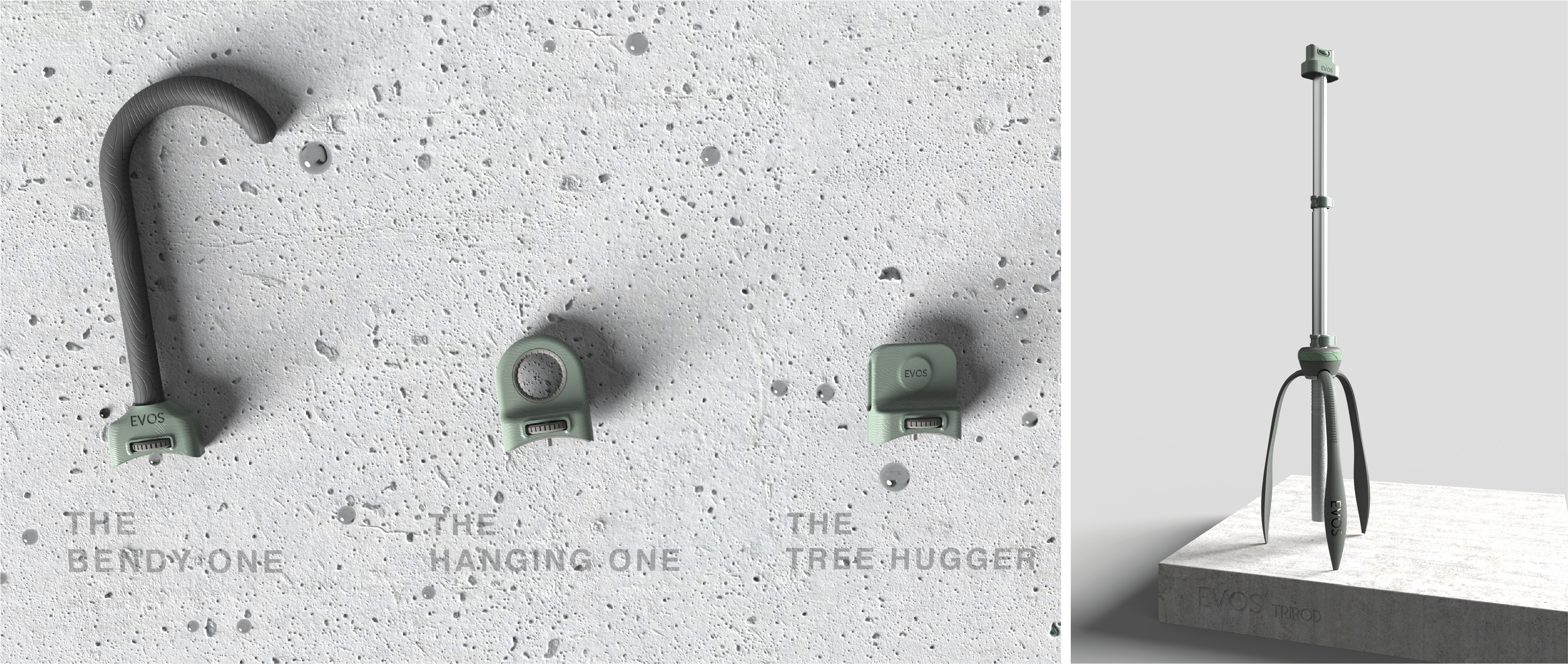

EVOS - Attachments.

To ensure the Explorer was as adaptable as possible, numerous attachments were developed to enable the camera to be secured in different scenarios. Increasing versatility of the product had the added value for more research projects, for example, the flexible attachment provides more options for arboreal studies.

EVOS - Prototype Testing and Iteration.

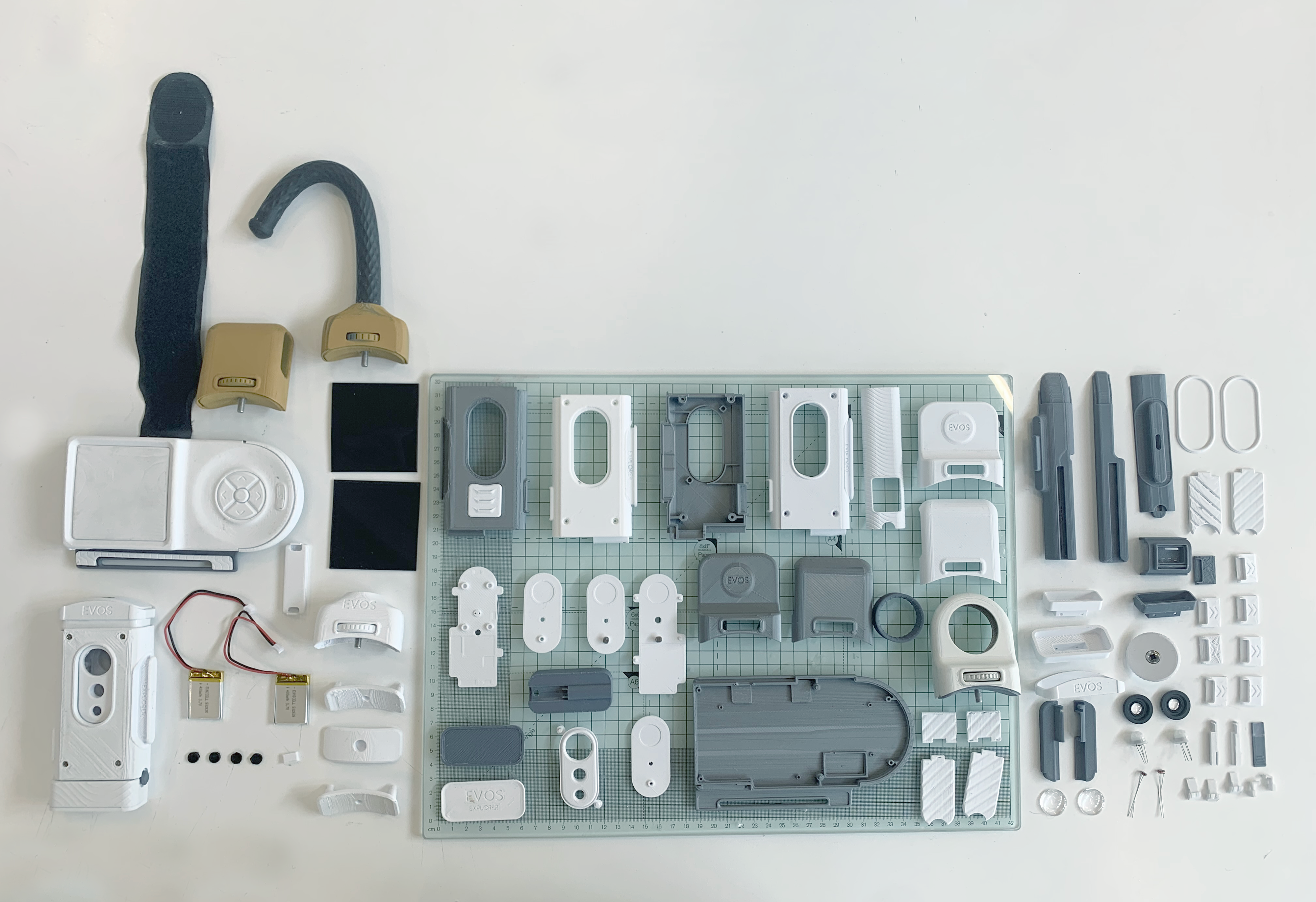

Prototypes of a varied fidelity were created all through the products' development process, enabling me to test mechanisms, act out scenarios with users and critique the aesthetic. Initial prototypes started as quick sketch models, later on, I produced a range of iterative prototypes often using FDM 3D printing techniques. Prototyping often focused on the different physical interactions of products, with testing heavily focussing on how the user would perform actions in different conditions and then how easy it was for them to do so.

EVOS - Explorer Exploded View.

Throughout the process of design, optimisation for manufacturing and assembly were meticulously considered. The internal structure was designed to ensure it was easy to assemble and disassemble, whilst a DFA analysis was conducted to reduce unnecessary parts saving time and cost. The products were optimised for injection moulding, redesigning parts to remove avoidable undercuts and ensuring draft angles were correct whilst minimising possible shrinkage across all components. Finally, the material selection process was rigorous, ensuring that chosen material blends would stand up to the harsh conditions they would have to face for long periods.

CHEF - Reducing energy in the home through efficient cooking practices.

Chef provides a unique and personalised experience for new renters, encouraging them to form energy-efficient cooking habits and motivating them to cook every day. Chef gives you the chance to run your own virtual restaurant from home, through consistent use you will progress your restaurant's reputation and eco ranking whilst improving your cooking skills along the way!

UVIE - Improving travellers' health and safety through better communication and hygiene practices.

I was tasked with designing a product which Airbnb could release in the post-Covid era. It was a very time-intensive project with just over a week to complete. I identified a problem of the need for greater management of physical and mental health within the travel industry. From this, I developed uvie. A two-part system; the hub acts as a UV sanitisation station using positive affirmations to encourage users to engage with the product. The handheld device provides a link between landlord and guest. It audibly delivers information about the surrounding area and accommodation reassuring the guest in their new location.

Gabriel Davies

Final year project

EVOS - Tackling global biodiversity loss through reinventing wildlife data collection.

Awards

19' Starpack Silver award winner. Awarded for my submission 'Urban Eyez', in response to the brief 'Design and Develop an exciting and eye-catching tin for a planning kit for street art supplies and equipment.'

21' Diploma in Professional Studies.

22' Design School Nominee for the student RSA Awards.

Work Experience

Dufort Associates 2019-2020

Here I gained experience working on a multitude of projects, whilst collaborating with a team of close-knit driven product designers and engineers. Work included ideating for future products, design of moulds for injection moulding, rapidly prototyping concepts to aid development and producing dimensioned engineering drawings used to aid manufacture. Often I would have to work directly with clients, working off the feedback given and ensuring all work was done to the required professional standards.

My time at Dufort Associates, taught me to work pragmatically and as I was often working remotely, I had to adapt the way I worked and communicated to avoid hindering project development.