I am a forward thinking designer and keen problem solver with a strong interest in design for manufacture.

Final year project

Football boot sanitiser, odour remover and dryer

Score Fresh

My final year major project.

As a sports player, there’s nothing worse than having a pair of boots that plague your house with an offensive smell. Score Fresh fits into a player’s post-training and game routine to keep their boots clean and odour free. All 'shoe sanitising' products on the market use Ozone or Ultraviolet light, both potentially dangerous to humans, this product focuses on using well known and safe technology to get the job done with lasting results.

The aesthetics of this project were particularly challenging due to the nature of the design. The arms that feed into each shoe dictated how the product would look. I always design around internal components, however for this project, I chose to reverse my model of working to force myself to put the most attention to the aesthetics of the product. So I had to separate myself from the comfort of DFM for a large part of the project.

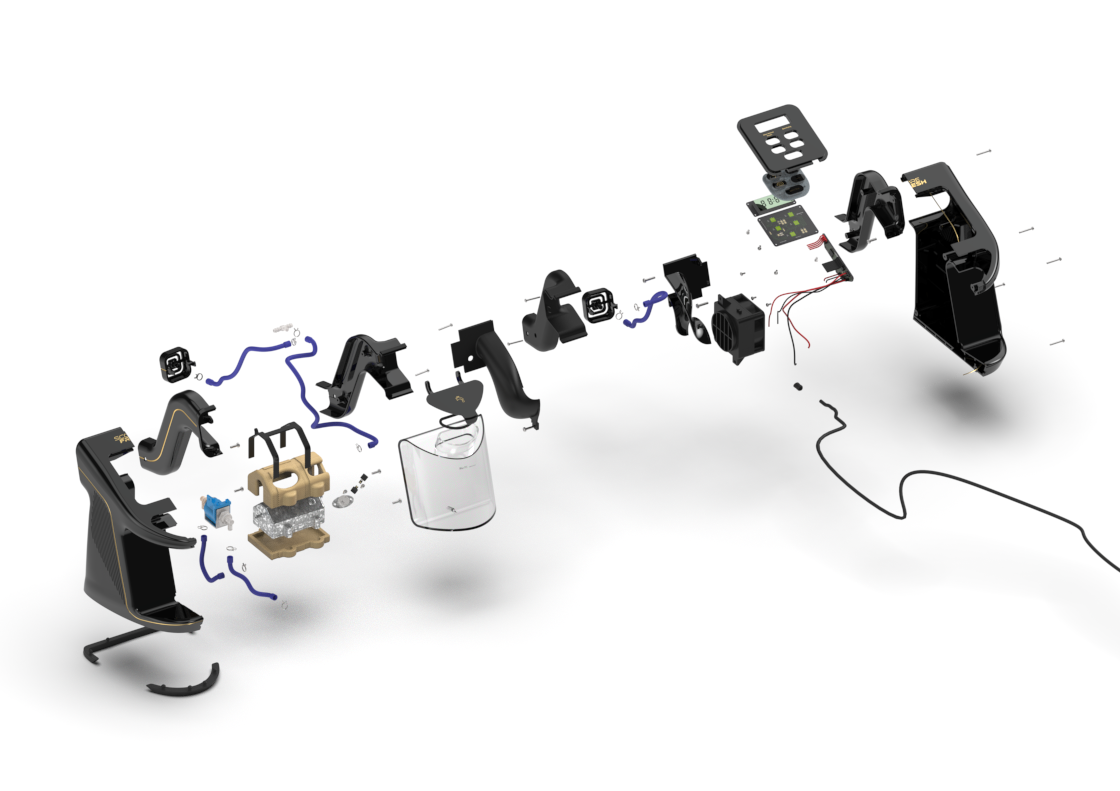

Score Fresh - exploded view

Once the aesthetics were cemented, I had to work around fitting the internals inside the product. It took multiple attempts to re-orientate the internal components and re-draw the split lines to allow all of the components to sit comfortably inside the product without impeding the assembly or manufacture.

Score Fresh has been designed with disassembly in mind and splits into two halves containing the heating and water components separately for ease of maintenance. As mentioned I am very interested in design for manufacturing. When I understand how a product works I am better able to connect with the design. As part of my specialism, I chose to model each and every internal at a 1:1 scale inside my product, to highlight how each component would interact with each other.

Arise - In context render

A new crutch designed for elderly total joint replacement (TJR) patients. It's designed to aid them as they walk, help them get onto and off of the floor to conduct exercises, and allow them to get up after non-serious falls, whilst creating a new and energised appearance to the depressive grey tones surrounding walking aids.

Due to high demand on the NHS, there's a 12-18 month waiting list for TJR operations and a minimum 6 week recovery time, but full recovery can take up to 2 years. This puts the elderly at extremely high risks because they lose 2-3x more muscle mass than younger generations during periods of inactivity that last 6 months or more. Throughout this recovery phase, the patients are recommended exercises that require laying down, which limits most to their beds as they are unable to get onto and off of the floor safely.

Falls, and the patient's fear of falling, are common before and after TJR operations due to sudden reductions in strength, and range of motion, resulting in a loss of confidence in their ability. This creates an isolated sedentary lifestyle. where most patients are confined to their houses which leaves many with mental health problems, as they are stuck inside with increased dependence on others.

This was part of a design sprint for my final year at university, where we had to go from a problem to a developed solution in a week.

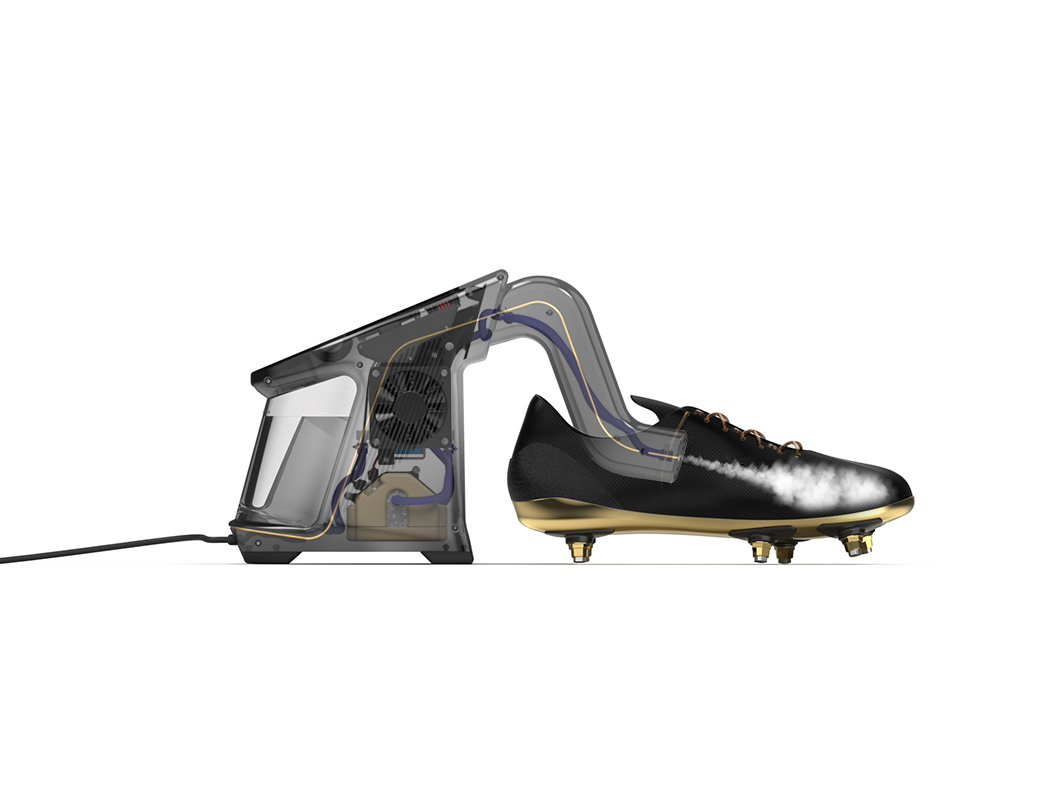

Score Fresh - Cutaway view

A working view of the Score Fresh. The shoes are hooked over the front of the arms and rested on the floor, meaning the product doesn't have to be moved to begin a steaming cycle. The exposed water tank allows the user to see how much water is in the product at a glance and the oversized water fill creates the easiest refilling experience.

Score Fresh - Interface detailing

Two pre-set buttons control the amount of steam the boots receive, which safely destroys the bacteria that cause odour.

The product pairs with scented de-ionised water to add an extra burst of fragrance to your boots. Featuring a fan assisted heater, Score Fresh can dry out a pair of boots after general use or a steaming cycle and can function as a boot warmer. The interface mounts on a modular and upgradeable base, with five easy-to-read tactile buttons raised from its surface.

Arise - Detail

User-friendly buttons - Large, visible and colour-coded buttons help the user around the product.

Unlock with red - The red button unlocks the ball from both positions so it can be moved along its path, an audible click assures it's in place and locked out.

Extend with blue - The buttons also adjust the leg, bipod legs and forearm rest to tailor the crutch to different users' heights.

Built-in suspension - The curved handle design absorbs the shock from ground contact impact, protecting the user's arms and wrists as they walk.

TPA grips - Softer pads are on the handles and the forearm rest for added comfort.

Arise - Adataptability

Arise transitions from fully folded to walking mode and then to floor model with simple buttons. The rotating forearm grips allow the user to complete tasks with ease, for example, they are able to set one crutch into floor mode, without having to hold the second crutch for support.

Familiarising TJR patients with getting onto and off of the floor increases their self-confidence in their ability to get up, reducing their fear of falling. This gives the user more choice of where to conduct exercises that require laying down promoting exercise and returning some of the independence that surgery took away.

CAD/CAMM optional module

The aim was to utilise Solidworks as a parametric modelling tool and use surface modelling along with 3D scan data to reverse engineer a physical product that has complex curved geometry.

The picture shows my final renders for the Ansio clothes steam cleaner that I reproduced with almost entirely surfacing tools, a tool I had not used previously. It was challenging learning a new way of modelling during my final year studies, but it has already proven extremely useful as I was able to bring surfacing into my major project and subsequently surfaced the entire model.

Abram Smith

Final year project

Football boot sanitiser, odour remover and dryer

Awards

As of May 2020, I am a Certified SOLIDWORKS Professional in Mechanical Design, awarded by Dassault Systems.

Work Experience

From June 2020 to July 2021, I was a product design intern at Oceania Defence UK, a registered firearm and home office certified, prohibited firearms dealer. Over the year I spent the majority of my time designing both firearms and component parts, such as optical sights and magazines. Not only did I build on my design skills and develop an in-depth understanding of mechanisms, but I also developed a business approach to design and vastly improved my communication skills as the first point of call when customers and businesses rang in daily.