I am a curious designer that thrives on a challenge and loves to get stuck into problems with a creative approach.

Final year project

Improving clothing care between washes to increase their lifetime and reduce environmental impact.

dew

The product refreshes clothing between washes, removing wrinkles and general odours so they can be worn again with confidence. Using water, clothing is steamed and then dried within the product. A closed-loop system reuses and recovers the water. Lack of agitation helps increase the lifetime of the clothing. Decreasing the frequency of clothes washing helps reduce the environmental impacts of microplastic pollution, discarded textiles, and water and electricity usage.

dew - Top View

Using the dial, a cycle is set and can be adjusted in intervals of 5 minutes, with a maximum runtime of 30 minutes. Within this cycle, clothes are steamed and dried so that they are ready to wear once the cycle is complete. A sole drying setting is also provided, and the length of can also be adjusted. A simple control interface allows users to easily interact with the product, increasing its desirability as minimal user interaction is required. The lid is pressed to pop open the product for loading and unloading clothing.

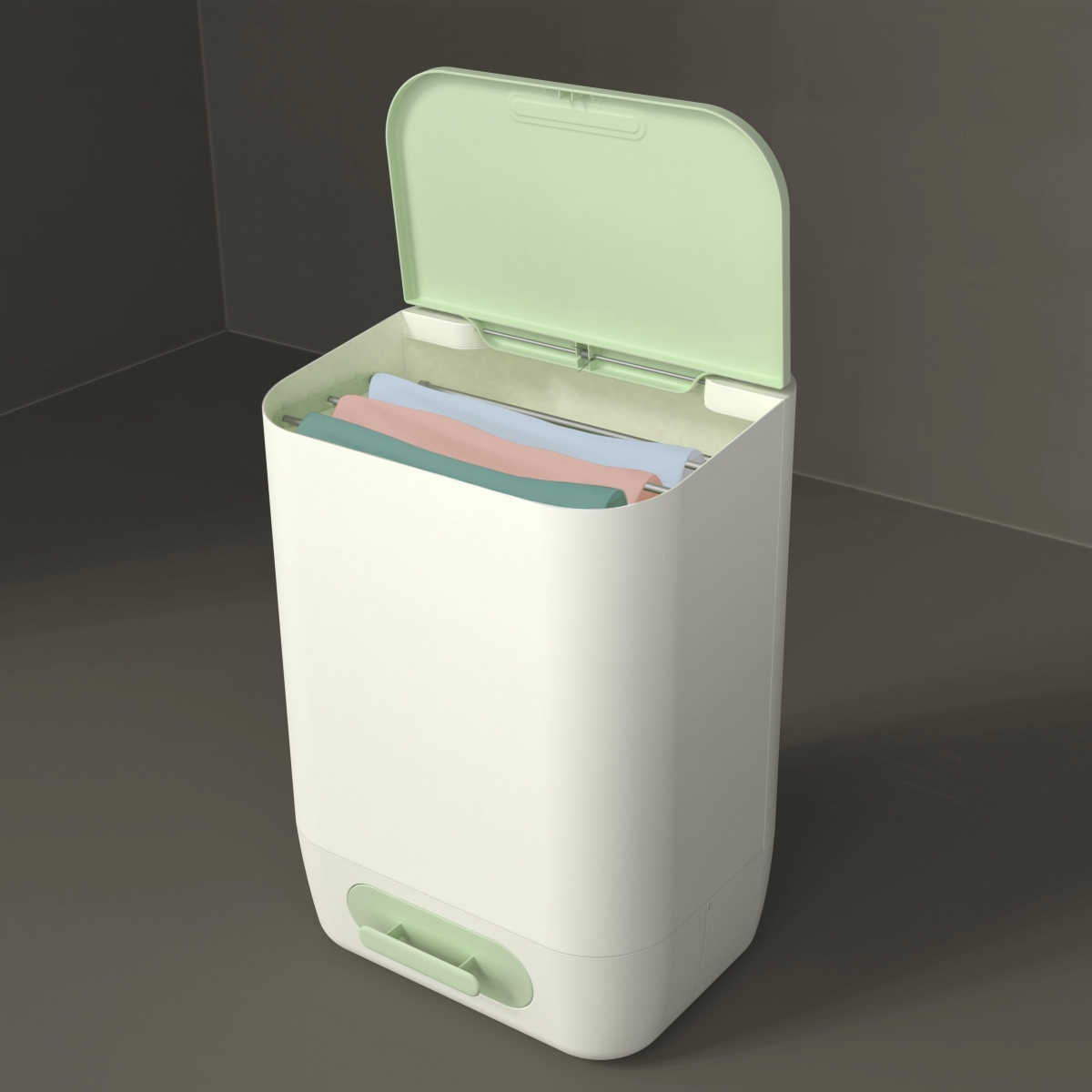

dew - Inside View

Clothing can be easily loaded and unloaded by opening and closing the push-to-open lid. The inside of the device reveals 3 horizontal rails that up to 3 shirts can be placed on. An extra attachment rail is provided which allows smaller items to be refreshed as well. The water tank is located at the front with a handle, allowing it to be easily removed for filling and emptying.

Déjà Brew

This is a prototype produced as part of a mechatronics group project in which the process of making an espresso or americano using an AeroPress was automated using C programming. Using laser cutting and 3D printing, a casing and parts were designed, iterated and constructed. The mechanical system was constructed and tested rigorously with electronic components to produce a working prototype.

you-v

For Live Projects, I designed a portable hand-held mask disinfector for the NHS. The product utilises UVC LEDs to kill bacteria and viruses on a mask when it is encapsulated and applied for up to 5 minutes. This allows disposable masks to be worn a few more times before disposal, reducing waste, and reusable masks to be worn with an increased assurance of safety.

Kruthika Kada

Final year project

Improving clothing care between washes to increase their lifetime and reduce environmental impact.

Awards

Diploma of Professional Studies 2021

Certified SolidWorks Mechanical Design Associate (CSWA) 2020

Work Experience

I completed a one-year industrial placement at Neal's Yard Remedies, working as a Student Packaging Technician within the Packaging Development team. Working in the packaging field allowed me to explore and develop new knowledge and skills. Neal's Yard Remedies prioritises sustainability in their beauty products, increasing my interest in the area. I proposed and designed packaging solutions which I presented to team members and suppliers. I conducted compatibility tests, factory line trials and transit trials, analysing results and presenting them back to my team to assist with problem mitigation. I carried out market exploration and research for upcoming product lines. Collaborating on projects with different teams within the company helped me understand the NPD process. I researched sustainable packaging, refill formats and circular economy solutions to provide suggestions on how the company could improve their sustainability for my placement dissertation.

I design, make and sell polymer clay and beaded earrings on an online platform, Depop. I have created branding and photographed the jewellery for marketing and promotion online. This has allowed me to expand my creative skill set and given me the opportunity to develop business skills, providing another avenue for career development.