I am a versatile designer that aims to design from the inside out to produce impactful product solutions

Final year project

Providing an effective solution to managing food waste in a domestic setting

Muurska - an easier way of managing domestic food waste

With the UK throwing away 9.5 million tonnes of food waste each year it is important to separate this waste where possible so that it can be reused to create products such as biogas. However, many people are discouraged by the bad odours and pests associated with traditional food waste bins. Muurska eliminates these pain points through an innovative mechanical system.

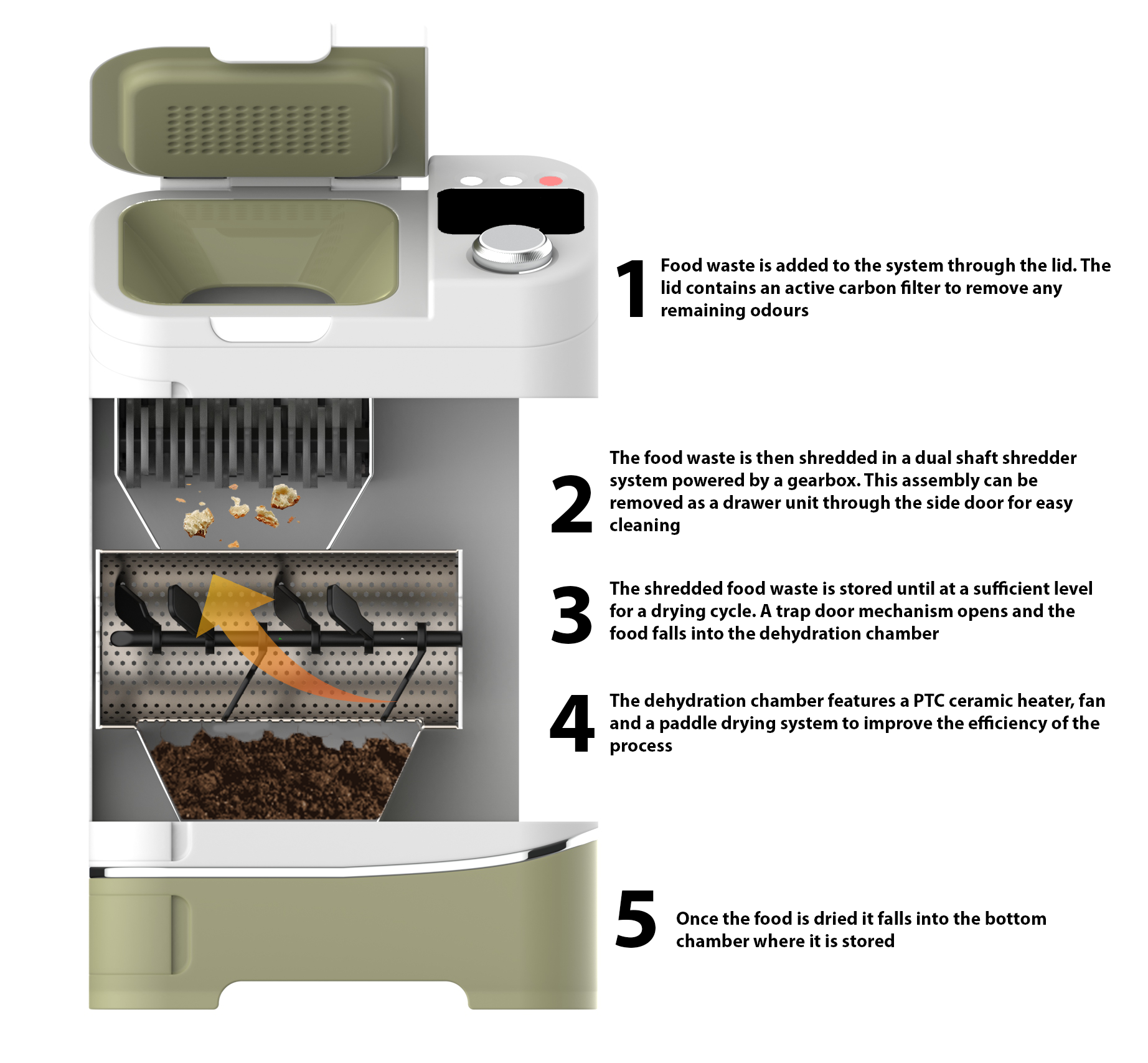

Muurska - Working principal

The system features a number of separate chambers which process the food as it flows through the system. The user experience has been well considered through user interface development and both the shredder and the dehydration units can be removed through the side door for easy cleaning.

Muurska - Working prototypes

Throughout the design process low and high fidelity prototypes were created to evaluate and test proposed concepts

Design Week - SALUS - Proposal

SALUS was a response to a 1-week lives brief - "Propose a physical product that Deliveroo could launch". The research highlighted that there is a considerable amount of riders not wearing helmets leading to injuries and sometimes fatal accidents. The project focused on creating a solution that would increase helmet uptake among delivery riders.

Design Week - SALUS - Proposal

The final design proposal was a Bluetooth connected helmet that used embedded pressure sensors to detect if the helmet was being worn. The user would then have to validate this in the app before being able to complete any deliveries. The Deliveroo branding was heavily analysed to inspire the product styling.

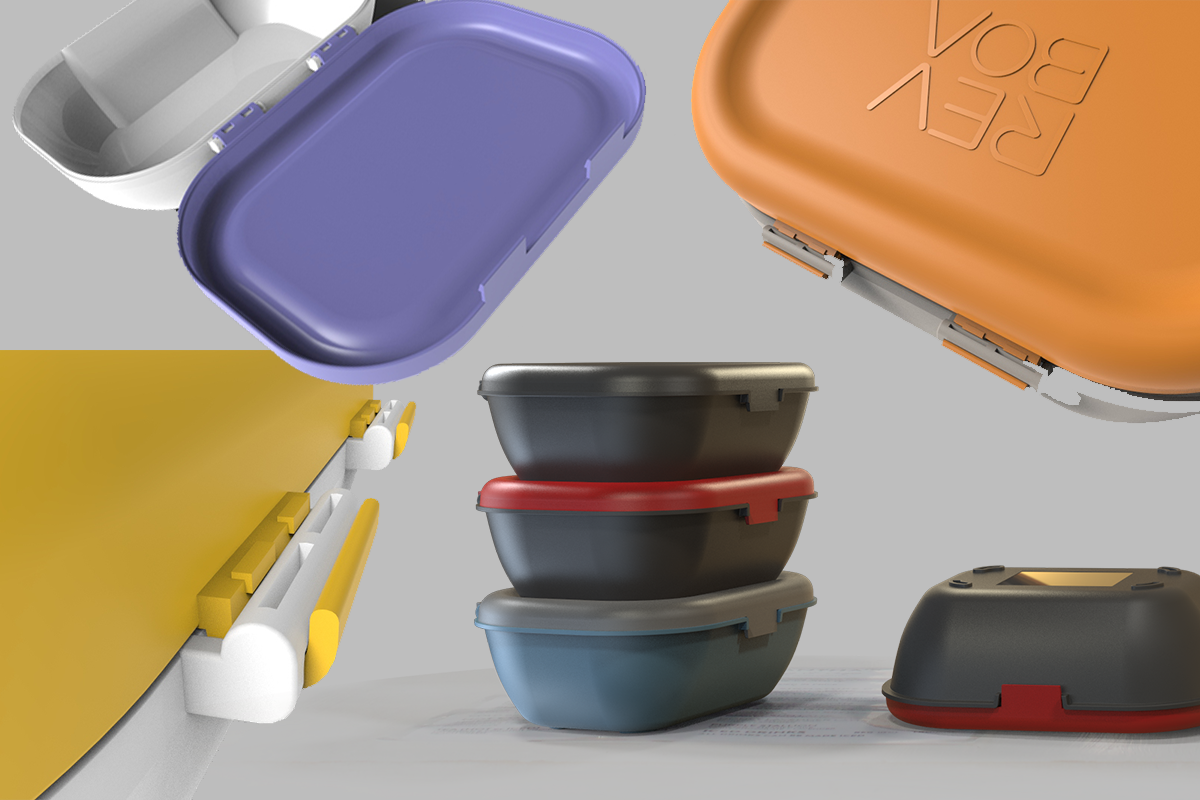

Placement project - Lunchbox redesign for manufacture

During my placement, I was given my own custom project to manage. I was tasked with the CAD redesign of a new smart container system to make it suitable for injection moulding. I was involved in a number of discussions with the client where I explained a range of designs for manufacturing decisions.

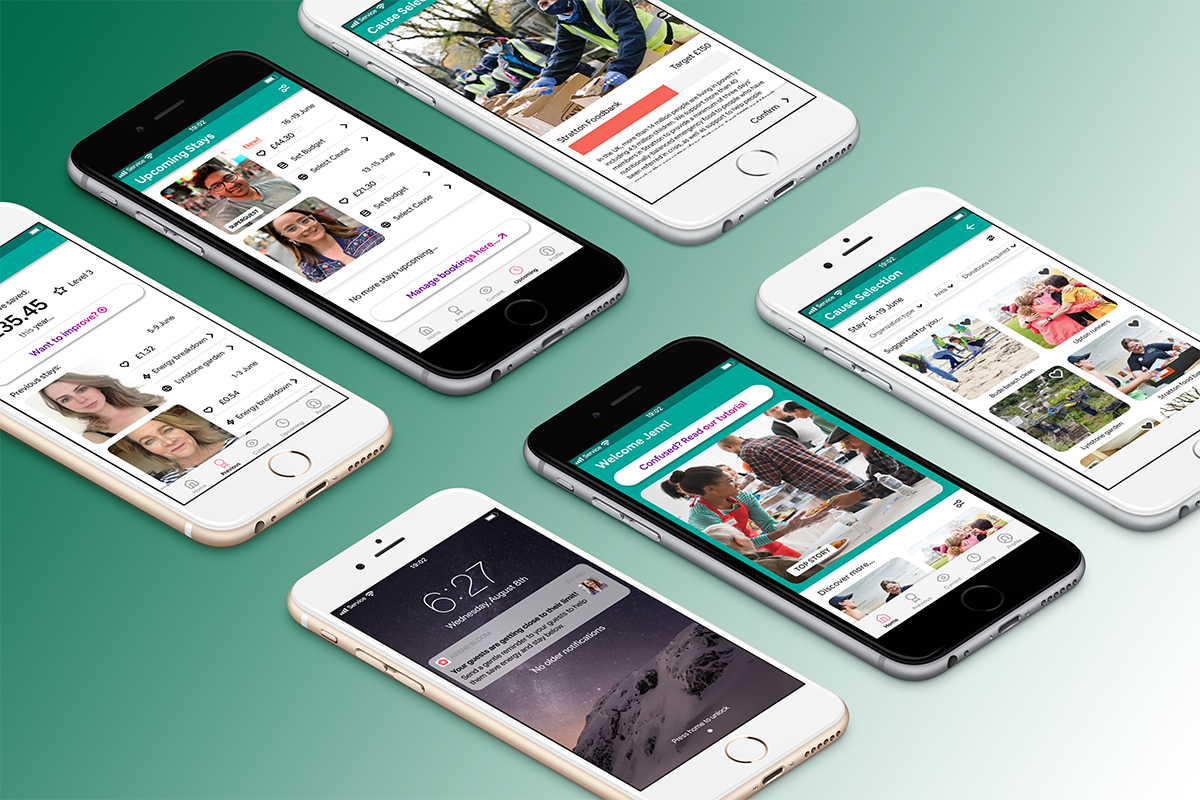

Bloom UX concept

For my optional module, I chose a user-centred design. In this module, we were set the task of designing an app to reduce domestic energy consumption. The initial concept direction selected explored Airbnb properties and excessive energy consumption among guests. Wire-framing and body-storming activities allowed for the app to be iterated until a final feature set for the app was created. The app allows for hosts to set a 'limit' for the guests and if the guest falls under this limit the remaining money is sent to a local community cause.

Automated Aeropress Coffee Machine

A group electromechanical project aiming to create a fully functional coffee machine making use of an 'AeroPress'. The final prototype featured a lead screw mechanism and self-rotating cleaning chamber. 3D printing, mechanics and electronics skills were well developed throughout the project.

Louise Briggs

Final year project

Providing an effective solution to managing food waste in a domestic setting

Work Experience

August 2020 - August 2021 Rutland Plastics

My placement was at an injection moulding company called Rutland Plastics based in Oakham. As a member of the design team, a key part of the role involved quoting parts for customers and offering them design for manufacturing advice where required. This was highly valuable for gaining technical knowledge of the injection moulding process and also developing essential workplace skills such as presenting to and communicating with customers directly. I also was in charge of running the in house 3D printer. This was a Stratasys Fortus 380mc system which could print in carbon-filled Nylon and ASA material and was used mainly for printing jigs and fixtures for the shop floor. I also assisted with the design of these jigs and fixtures and often would work closely alongside the automation team. Due to the varied nature of the role I had to learn to effectively manage a range of tasks daily in order to meet the tight deadlines of manufacturing. The year I spent with Rutland was extremely valuable as I was lucky to experience working in many areas of the company whilst also learning and developing key design skills for the future.