A creative designer who enjoys solving problems through an iterative, cyclical and thorough design process.

Final year project

Quick Catch - improving the recovery time of a conscious man-overboard (MOB) from a boat

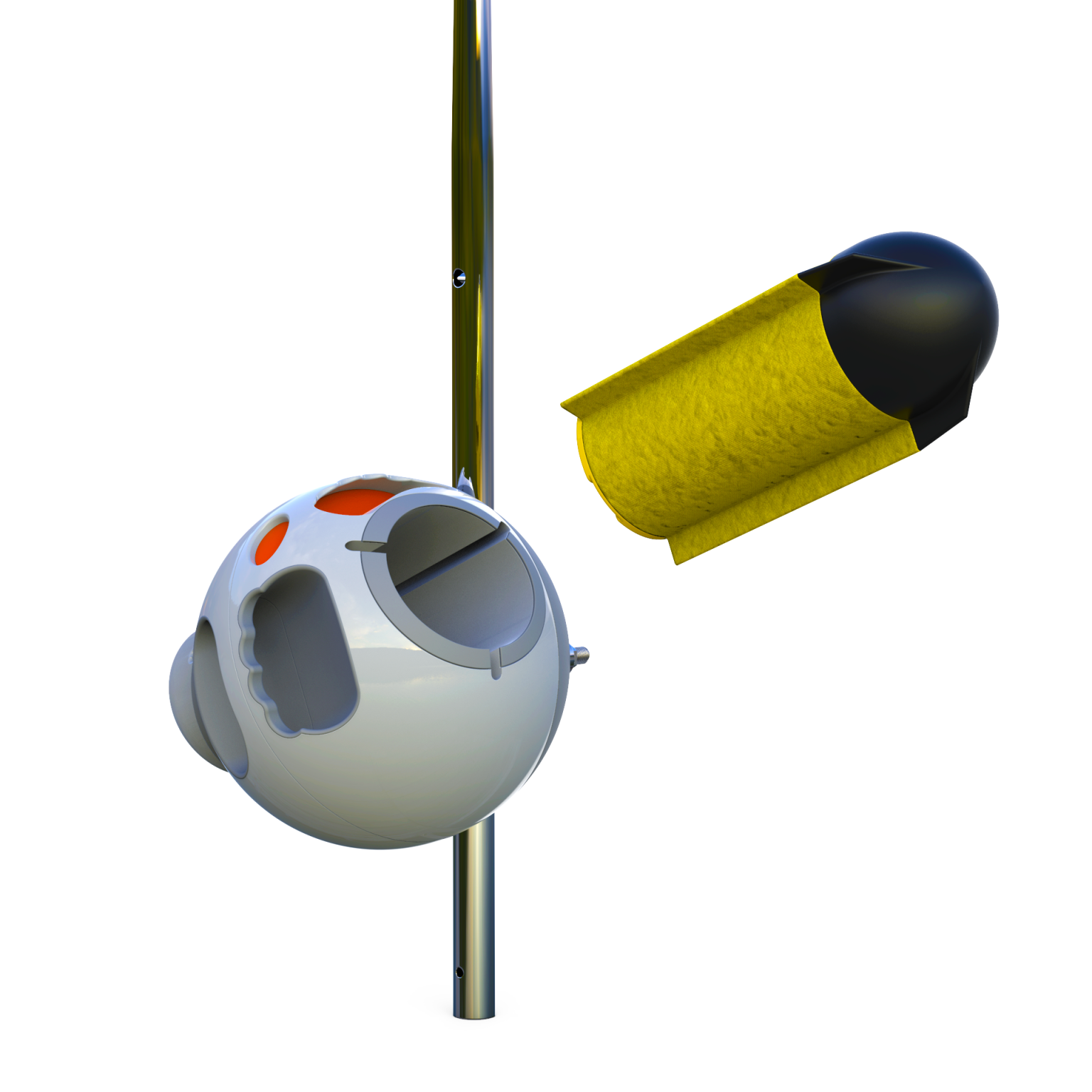

Quick Catch - Firing Mechanism

Quick Catch is designed to improve the chances of survival in man overboard (MOB) situations by deploying emergency equipment without relying on human reaction times or competency.

Quick Catch comprises of two main elements – a wearable and an automatic firing mechanism.

The wearable detects the fall overboard and uses GPS and real-time kinematic positioning to track the casualty’s position in the water.

When the casualty comes into range, the firing mechanism sends an automatic life preserver and connected lifeline into the water. The combination is designed to reduce the risk of drowning and improve rescue times - vital in cold water.

The foam-cased projectile is deployed up to ten metres using a small 16g CO2 cartridge linked to a receiver tank and pneumatic flow valve.

By removing the firing mechanism from its dock on the stanchion post, Quick Catch can also be deployed manually from anywhere on the boat.

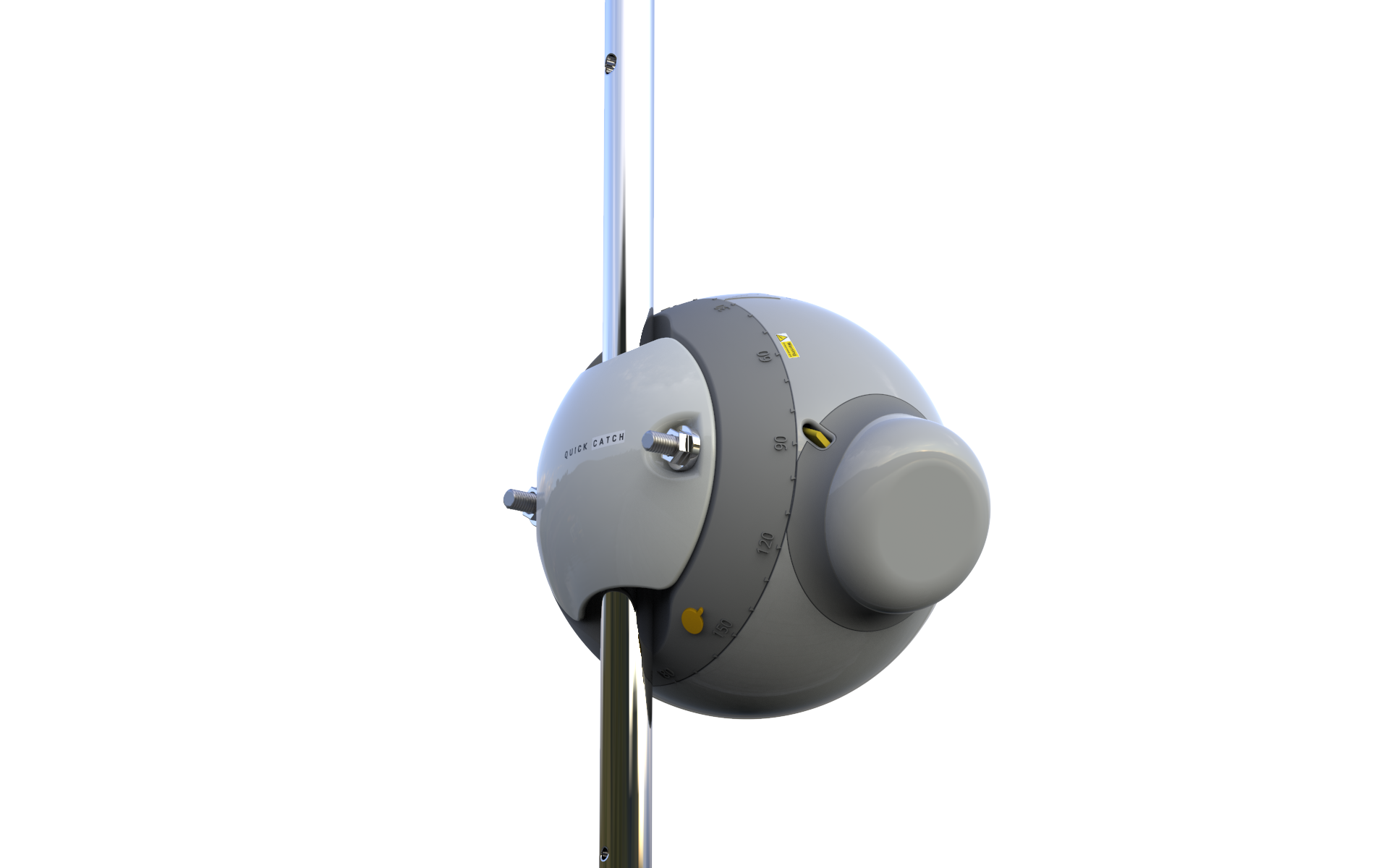

Quick Catch - Spherical Design

The spherical design ensures that it does not interfere with any boat handling activities. When mooring stern-to for example, any lines going ashore should simply slide off and not get snagged. It should also not interfere with people moving around the boat.

Quick Catch - Prototype Development

This system was tested to see if it meets the 10-metre requirement set out in the product design specification. Following this, iterative changes to the projectile's aerodynamics were made to increase its stability and performance.

Quick Catch - Projectile Developement

The projectile houses an automatic life preserver - this helps locate the MOB in the water which can be particularly difficult in rough weather and with poor visibility. It also provides crucial buoyancy, reducing the risk of drowning and improving rescue times- vital in cold water.

A flap opens (held in place with magnets) to allow the life preserver to inflate in contact with water.

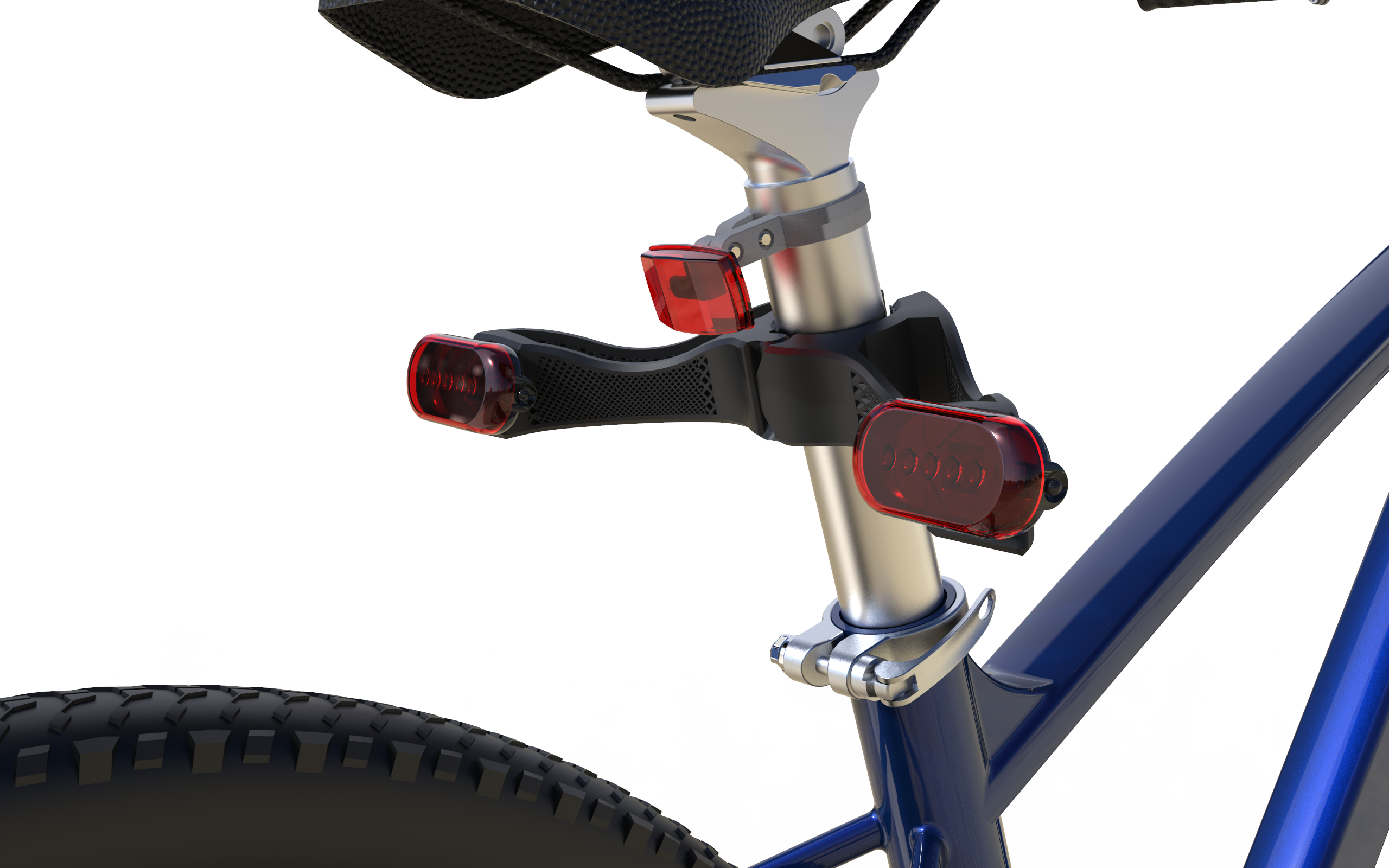

Bike Light Fixing - Visualisation

Using generative design to create a bike light fixing. This project advanced my grasp of using 3D printing as a manufacturing method along with the constraints and flexibility that it provides as a process.

I also learned how to use topology optimisation and generative design in Fusion 360.

Bike Light Fixing - Prototyping

The design uses TPU and ABS through a dual extrusion printer (RAISE 3D Pro 2). The project utilised CES material selector to narrow down material options.

I also calculated the costs to produce a batch of 1000 front and back lights

Bike Light Fixing - Lattice Structures

Using SULIS by Gen3D I created lattice structures for the front and rear lights, this lightweight design whilst maintaining its strength. Modifiers were used to adjust the density of the lattice in different areas.

The backlight fixing (pictured above) is designed to clamp around the seat post using a hinge and ratchet-style mechanism. All of the hinges and mechanisms were printed in place so no assembly nor supports were required.

A surface lattice (gyroid) was implemented around the clamping faces to provide a textured surface so that the light fixing did not slide down the seat post.

Sam Baldwin

Final year project

Quick Catch - improving the recovery time of a conscious man-overboard (MOB) from a boat

Awards

Diploma in Professional Studies - Issued by Loughborough University

Work Experience

Idea Reality - Design Consultancy

Junior Designer - 20-21

Working with the team at Idea Reality hugely helped my management skills. Regularly presenting and talking with clients and suppliers to help move projects along swiftly and efficiently.

With the level of responsibility given to me and the support of the team, I learned a lot of new skills this year and continued to develop existing skills such as electronic prototyping too. Working on a huge variety of different projects also helped me broaden my skill set and focus on areas that I hadn't had as much experience in such as designing for manufacturing.

I am looking forward to joining the team again in September 2022 and continuing to develop as a designer with them.